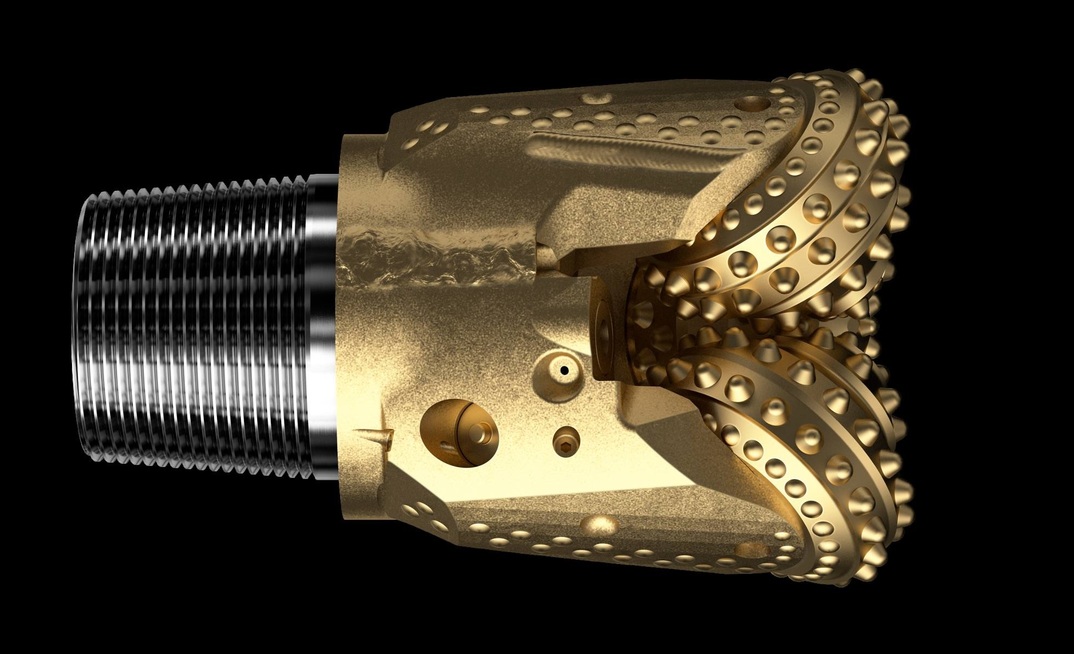

PRESS RELEASE: The RR441 is an improved version of the RR440, designed to last up to 140% longer than comparable rotary bits such as the Sandvik R222 rotary drill bit, a previous equivalent product. With an extended bit life and fewer bit changes, the RR441 can maximise drilling uptime, providing a lower cost per metre and potentially setting a new industry standard.

Sandvik stated that the Sandvik RR440 range of rotary bits has remained the benchmark for drilling excellence for 15 years. The launch of the Sandvik RR441 is designed to help bring the drilling industry into the future. As a new and improved version of its predecessor, the Sandvik RR440, the RR441 is designed to provide excellent class-leading bearing life, simplification of the bearing system, improvements in air flow and superior wear protection in soft rock applications.

Simon Mitchell, vice president, rotary tools at Sandvik Mining and Rock Technology, said: "Today it is more important than ever for our customers to maximise the value of their investments, and Sandvik RR441 delivers. Our latest range of rotary blasthole bits features advanced cutting structure design for optimal bottom hole coverage and maximum penetration rates. The bits have better longevity thanks to multiple design improvements, where we have matched our proprietary Sandvik cemented carbide shapes and grades to specific drilling conditions. This will help to reduce wear and breakage, further increasing bit life and providing an easier-to-use product."

Sandvik RR441 sizes range from 171mm to 406mm, and are now equipped with an improved durability dual seal journal bearing.

The Sandvik RR441 has been developed according to three main principles, each of which provides a distinct benefit: reliability, application-focused cutting structures and a complete, combined offering.