Optimizing Mining Efficiency: Value-Added Solutions for Grinding and Crushing Efficiency

ME Elecmetal designs solutions to help our customers achieve their goals by combining wear parts with technology tools, advice, training, and monitoring — all of which allow us to create value in our customers' processes.

ME FIT®: Fully Integrated Technology

Drawing on more than a century of experience in the mining, aggregate, and recycling sectors, ME Elecmetal's ME FIT Crushing and ME FIT Grinding optimization programs provide customized solutions to tackle the specific challenges of each mining operation. Our goal is to assist customers in realizing their production strategies and productivity targets.

With our ME FIT programs, we offer comprehensive solutions that bring tangible benefits to our customers' operations. Engineered to boost productivity significantly, these solutions enable more streamlined and efficient processes. ME Elecmetal is dedicated to continuously improving the performance, efficiency, sustainability, and success across all facets of our client partnerships. This commitment fosters enduring relationships with our clients, rooted in trust.

Innovative Products, Services, and Solutions Engineered to Deliver Significant Value

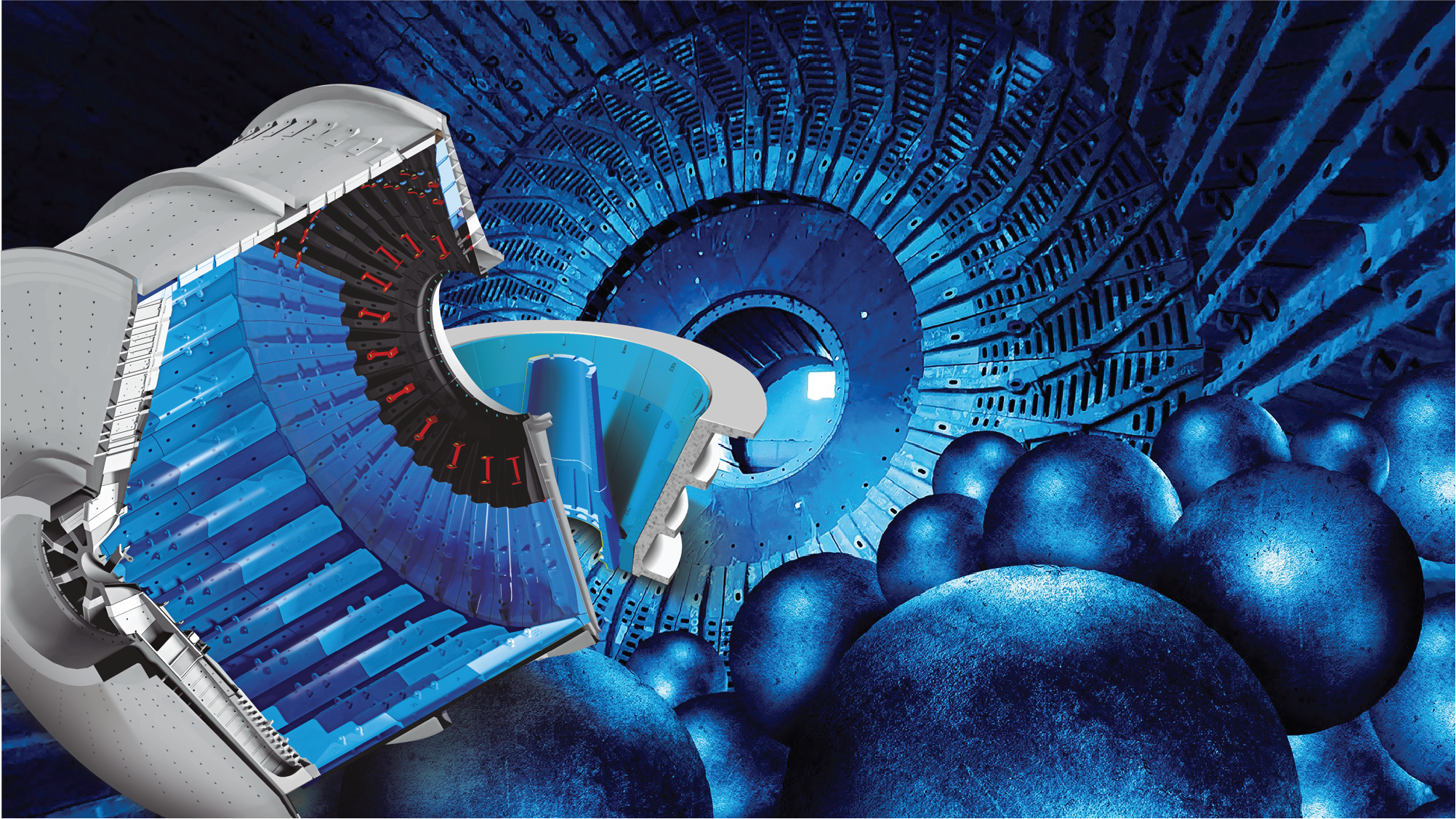

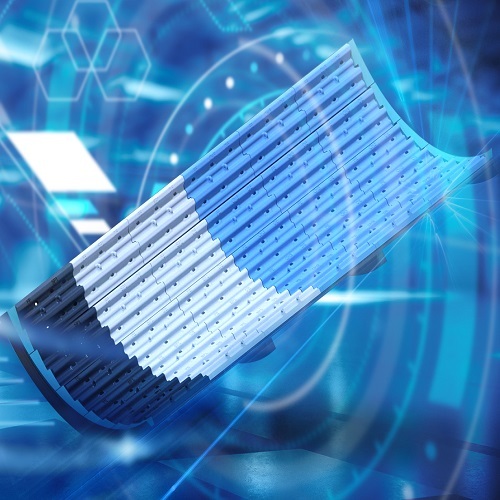

Mill Liners for Optimal Results: Elevating Performance and Efficiency

Grinding mill liners play a crucial role in achieving peak mill performance. At ME Elecmetal, we prioritize innovation in liner and alloy designs, aiming not only to deliver proven performance but also to minimize costly relines and downtime. Through close collaboration with our customers, we conduct thorough analyses of their operations to identify the ideal combination of design and materials for their equipment. Each liner undergoes detailed customization to ensure optimal performance, with continuous monitoring of wear performance and production rates throughout the process.

Our solutions consistently surpass customer expectations, offering the lowest total cost of ownership. You can rely on us to uphold the highest quality standards and utilize cutting- edge technology to ensure unmatched strength and durability, enabling you to operate your mills with confidence and efficiency.

Optimizing Safety and Reliability with Crusher Wear Parts and Safety Tooling

ME Elecmetal leads the way in delivering exceptional wear solutions for crusher operators across the mining, aggregate, and recycling sectors. Our commitment to innovation and excellence ensures we offer the best-in-class Crusher Wear Parts, customized to meet the distinct requirements of every application. Whether for primary, secondary, or tertiary crushing, we engineer our parts using premium alloys for unparalleled durability and performance.

Recognizing the challenges our customers encounter, we place utmost importance on safety, durability, and user-friendliness in all our products. Our extensive lineup of Crusher Safety Tooling is designed to enhance operational efficiency, ensuring tasks are completed safer, faster, and smarter.

You can rely on ME Elecmetal to not only meet but surpass expectations, seamlessly adapting to any equipment you have on-site, thereby ensuring your operations are optimized for maximum productivity and minimal downtime.

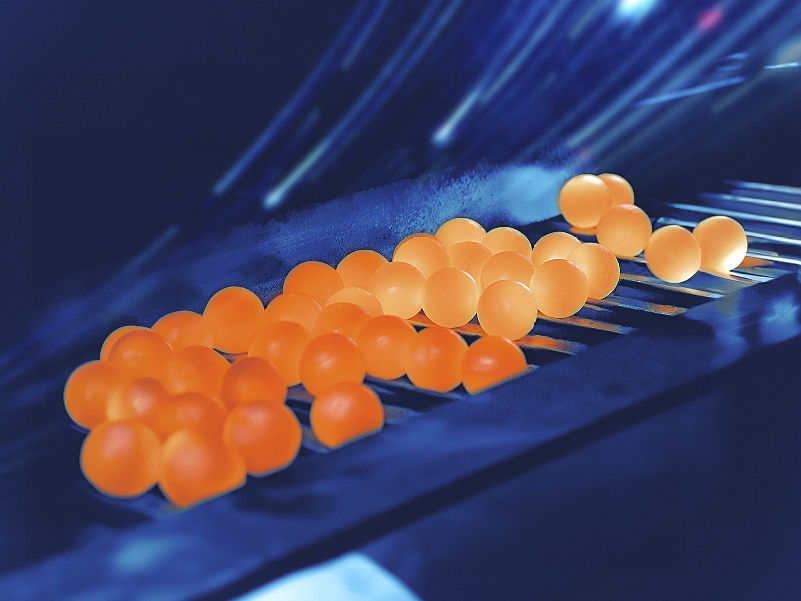

Advancements in Grinding Media: Driving Continuous Improvement

ME Elecmetal leads the way in supplying premium forged steel grinding media for SAG, ball, tower, and rod mills worldwide. Leveraging extensive field experience and engineering expertise, we serve as invaluable partners in driving continuous improvement within your grinding processes.

Our dedicated team of sales and application engineers is readily available to analyze operational data, refine media charging practices, and optimize grinding media consumption, ultimately enhancing throughput. You can rely on us to deliver the grinding media to your site and provide unwavering support until your final product emerges from the mill.

Backed by substantial experience and large-scale grinding media production capacity, ME Elecmetal solidifies its status as a strategic partner in the global mining market. Together, we strive for operational excellence and efficiency, ensuring your success in the industry.

Fostering Innovation Through Expertise and Technical Know-How

Driving Productivity Forward with Optimization Tools and Services

ME Elecmetal leads innovation in the mining industry, harnessing advanced digital tools to revolutionize grinding and crushing operations. Our optimization approach surpasses conventional methods by leveraging data analysis on a large scale. This enables us to craft customized solutions addressing clients' specific challenges, elevating operational efficiency and productivity. Our optimization suite provides insights and wear monitoring, ensuring every decision is data-driven for peak performance. However, our dedication to clients extends beyond innovative tools.

We provide unparalleled technical support and training tailored to empower our clients and their teams with the expertise and skills for optimal performance. Our services encompass 3D laser scanning for precise wear analysis, reline optimization to minimize downtime, and continuous improvement programs fostering operational excellence.

At ME Elecmetal, we recognize that success in the mining industry demands advanced technology and steadfast client support. Hence, we equip you with the tools, knowledge, and ongoing assistance essential for elevating your mining operations. Discover the possibilities with ME Elecmetal and unleash the full potential of your mining ventures.

Contact Us Today!

For over a century, ME Elecmetal has been a premier global supplier, offering comprehensive wear product solutions for the mineral processing, aggregate, construction, and recycling industries. With an extensive range of products and services, including grinding media, mill liners, crusher liners, and large specialty castings, ME Elecmetal is the preferred supplier for mineral processors looking to optimize their grinding mill processes. With a workforce of over 1,300 employees and a presence in more than 35 countries worldwide, you can rely on ME Elecmetal to provide the expertise and support necessary for your success. Discover more about our ME FIT and other solutions by visiting www.me-elecmetal.com or contacting us at 480-730-7500.

ABOUT THIS COMPANY

ME Elecmetal

ME Elecmetal is a global supplier with more than 100 years of experience as a supplier and strategic partner for total wear product solutions in the mineral processing, aggregate, construction and recycle industries. We are the preferred supplier for mineral processors seeking improvements in their grinding mill processes. Our range of products include: grinding media, mill liners, crusher liners, large specialty castings, slag pots and ground engaging tools. Our range of services include: service centers, engineering and design, Early Alert and ME FIT System®. ME Elecmetal has 1,200+ employees and serves customers in 35+ countries around the world.

United States Offices

- 4500 S Lakeshore Drive, Tempe, AZ 85282, 480-730-7500, United States

- 3901 University Ave NE, Minneapolis, MN 55421, 763-788-1651, United States

- Tel: 4807307500

- Email: marketing@meglobal.com

- Website: www.me-elecmetal.com