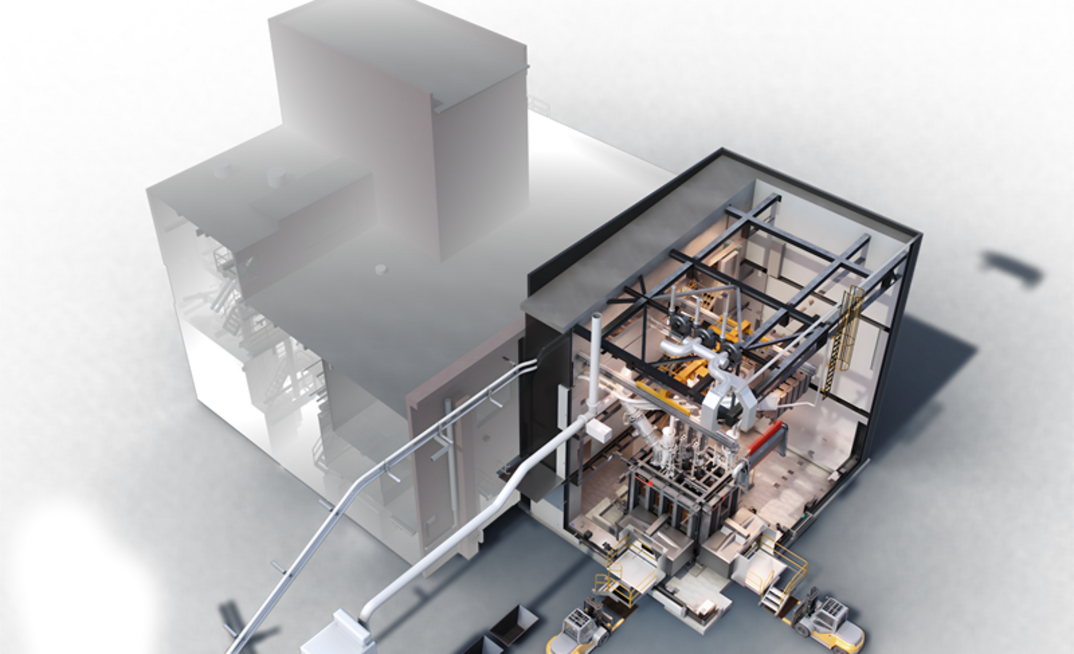

The pilot plant, to be built in Pori, Finland, will enable customer-specific testing to demonstrate the viability and benefits of using Metso's furnace technology for large-scale direct reduced iron (DRI) smelting.

The iron and steel industry currently accounts for approximately 8% of global carbon dioxide emissions, according to a statement by Metso. But growing environmental regulations mean that the industry is actively seeking innovative solutions to reduce its carbon footprint.

Launched in 2022, Metso's DRI smelting furnace addresses this need by replacing traditional blast furnaces in iron and steelmaking. It can be integrated with Metso's hydrogen-based Circored process or other direct reduction technologies, enabling primary steel producers to significantly reduce CO2 emissions while minimizing alterations to existing production lines.

DRI is a metallic product obtained by removing oxygen from iron ore without melting it. Unlike blast furnaces, the process uses reducing gases like hydrogen or carbon monoxide, derived from natural gas or coal, at temperatures below iron's melting point.

This results in a sponge-like iron material with a high iron content and minimal impurities. When combined with a direct reduction plant, the technology significantly reduces emissions, Metso claims.

Metso views this pilot facility as a crucial step in supporting its customers' transition to more sustainable steelmaking practices.

The furnace is a key contributor to the company's 'Planet Positive' initiative, which was launched in 2021 to highlight Metso's most environmentally efficient technologies.

"The rapidly increasing customer demand for reliable testing in their transition to emissions-free smelting has prompted this investment in the DRI Smelting Furnace pilot facility," Mari Lindgren, director of smelting research and development at Metso, explains.

"The facility will allow us to test various customer materials for industrial-scale application. Construction has already begun, and we expect to conduct the first tests later in 2024. Until then, we continue to offer smaller-scale laboratory testing services."