Showcasing the firm's ambitions, it launched a major brand revitalisation alongside a landmark new engine in September. Both were designed to underline a renewed commercial outlook that focuses on power density, alternative fuels and hybrid powertrains rather than bigger iron and raw power.

"Ultimately, there are multiple power solutions. Some will be optimal for some situations and not others", said Matt Coleman, product director, at a press event atop London's iconic Shard.

"We're moving into a world where the solution could be a battery, a plain engine, or it could be a hybrid system, diesel, hydrogen, or biodiesel or alt fuels. Our customers also don't have endless resources, so it is our job to listen, help them choose the best power solutions and integrate these in a much smarter fashion than we have in the past."

Coleman noted that the shifting legislative, political and financial landscape is making the world ever more complex for its off-road customers - Perkins has been a subsidiary of Caterpillar for over 25 years.

"Customers today are faced with regulatory challenges which are no longer harmonised. In the past, there was Europe and America. Now we have China and India coming on board with high regulation, and they're all quite different, and in some instances, remarkably so."

"We're also having to deal with changing social pressures. We must comply with people's emotions and feelings about a product."

‘Agile explorers'

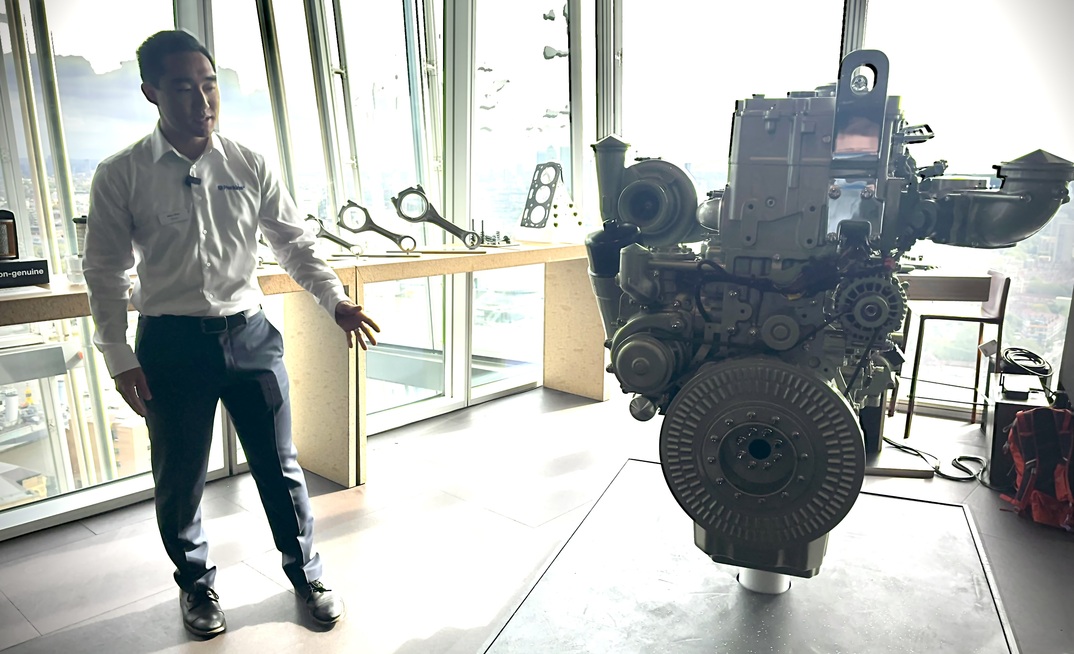

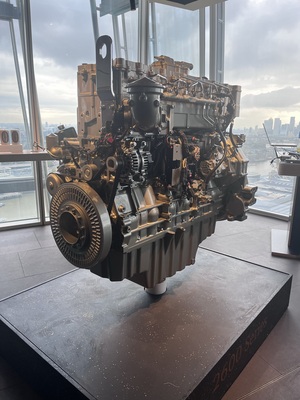

Perkin sees its new 2600-series, a 690hp, 13-litre straight-six engine, as a prime example of this new approach, exemplified as the vision to become "agile explorers" in a company mission statement.

Despite generating the same power delivery as 15- or 18-litre counterparts, the engine was designed for unprecedented levels of fuel efficiency and power density. It offers a considerably smaller physical and environmental footprint - both in terms of noise and emissions.

The engine designers needed to take a unique approach to balancing performance and durability while designing for manufacturability and compatibility across numerous sectors and applications.

"You can simply deliver more fuel and air to pack a lot of power into a small package" said Product Marketing Manager, Allen Chen. "Just look at Nascar, and Formula 1 cars for how that can be achieved. But for Perkins, that has to be balanced with durability and robustness. We would never take a racing car engine and put it in one of our applications, which undergo heavy-duty work for thousands of hours a year."

The company was also keen to showcase the digitalisation potential for the new engine, which is studded with internal and external sensors that can collect, analyse and integrate key engine performance data within a connected intelligent platform. The architecture is space-protected to accommodate configuration adjustments anticipated for future tiers of emission standards in the US and EU without relocating customer connection points.

The Perkins 2600 Series engines meet the EU Stage V emissions standards, which are among the most stringent in the world. This means that the engines produce very low levels of harmful emissions, such as particulate matter (PM) and nitrogen oxides (NOx). Perkins 2600 Series engines also meet the U.S. EPA Tier 4 Final emissions standards, which are similarly strict.

Critically, the engine is designed to be future-proof on multiple levels.

"This engine is foundational to a lot of our exploration in alternative fuels and related technologies," said Chen. "It can be coupled with a Motor Generator Unit [hybrid powertrain component] it can be employed in conjunction with the advanced controls, optimizing not only the engine but also the entire system, including the chassis and transmission, when given access. This is why advanced controls are so potent."

Electric dreams

The company's representatives highlighted that Perkins is ready to embrace electrification - including battery solutions - and leverage its workforces' forward-looking expertise. Rather than solely rely on its history of diesel engine innovation, albeit a proud one.

"In terms of that agile learning approach, we've got 90 years of experience in engines. From a battery point of view, we've got around five, six years in terms of development of our product. So it's really important to consider, there's lots more to learn in this space, from a hardware perspective, and from a software perspective" said Perkins engine sales manager Ricky Watts.

It is important to ask, "how is electrification actually going to work for our customers?" he added.

"I expect we will gain learning as we go on that journey, that collaborative journey together, to learn and follow as well. There may be mistakes as we go on this journey, but it's how we learn from them, and improve on those moving forward."

Watts relayed details of the company's recent collaboration on a battery-powered wheel loader.

"With the Volta 300 we took the complete system and integrated our battery alongside additional electrical electrification components. To demonstrate to our customers, that we can install these products into machines, and really understand how they operate."

Beyond the major overhaul of its battery ambitions and plans to transform its approach to traditional combustion engines, the company also plans to develop a unique plug-and-play engine that can be adapted for multiple types of alternative fuels.

Project Coeus

Called Project Coeus after a figure in Greek mythology who symbolised the pursuit of knowledge, the power of questioning, and the vastness of the cosmos, the envisioned engine will be capable of digesting ethanol, methanol, biomethane or even hydrogen.

Supported by UK Government funding of £11.14M through the Advanced Propulsion Centre UK (APC), Project Coeus will develop a 7-litre Perkins 1200 Series industrial power unit with hybrid-electric components and advanced controls to enable operation on hydrogen fuel.

The 45-250 kW hybrid powertrain system will be configured with factory-installed ECM sensors, radiators, cooling packs, filtration, control systems and after-treatment hardware in an integrated package that aims to minimise OEM development timelines and reduces engineering and assembly costs.

The Coeus engine will share components and software, while supporting the different characteristics of these fuels, said Paul Moore, head of Powertrain System Integration Engineering - Industrial Power Systems division.

"Essentially, we're going to take advanced systems, and integrate them into compact drop-in solution that is easy for an OEM to integrate … We're going to need to have spark-ignited capability to burn all of these future alternative fuels. But doing that in a way that provides the flexibility to deal with different fuel types is the real innovation."

"Regardless of how well you combust the alternatives, they perform differently to diesel, it's just physics. And the way that we will mitigate that and essentially, add the performance, bringing the performance that we sell today back into the product, is through harmonisation".

Moore said that Perkins has unique strengths in its plans to bring the engine to market.

"We can capitalize on our battery and hybrid technology expertise, integrating them holistically to create a product that seamlessly transitions from the current offering. Now, the true ingenuity of this concept, as a recurring theme throughout these presentations, lies in how we virtually connect and control all these elements. This is a genuine differentiator for our brand and enterprise. It may not be widely known, but we possess the in-house capability to develop all the software powering these products. This is a unique advantage in the industry, one that few other OEMs can claim."

The three and a half-year project will be led by Perkins' global engineering headquarters in Peterborough, UK, with Equipmake providing epowertrain technology and Loughborough University supporting through advanced engine analytics and emissions control.