The Emesent journey commenced in 2018 and has since delivered remarkable growth, becoming a market leader in the mapping of underground operations.

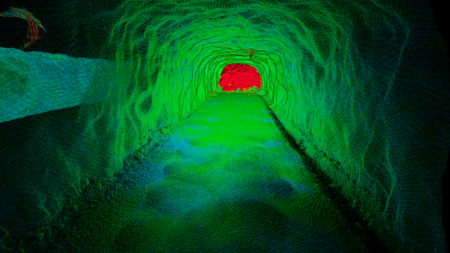

Typically, but not exclusively, deployed via a drone platform, Emesent's SLAM (simultaneous localization and mapping) based LiDAR scanning technology underpins the impressive data quality of their versatile solution Hovermap.

The clear value proposition is twofold; the ability to send piloted, or automated devices into potentially dangerous areas, whilst simultaneously capturing a significantly richer dataset than traditional methods.

These richer datasets provide significant value during reconciliation, in stope mapping of geological structures, and in capturing data in environments deemed too high risk for people to enter.

This data is now handled with ease by leading mining CAD packages, as outlined by Farid Kendoul, CTO and Co-founder of Emesent, "By generating 3D data in a standard format compatible with leading mining software like Deswik and Maptek, we enable seamless integration with existing systems. We've developed streamlined workflows for ingesting Hovermap 3D data, ensuring compatibility and ease of use for our customer base."

"Our commitment to interoperability extends beyond software integration. In various projects, we've successfully integrated our technology with other systems, amplifying its utility and accessibility," he continues.

This can clearly be seen with the integration beyond the various drone platforms that the Hovermap unit has traditionally been famous for.

Emesent's latest integration allows the Hovermap, a device celebrated for its autonomous navigation and 3D LiDAR surveying capabilities, to work with the Boston Dynamics Spot robot. This partnership has already proven valuable in active underground mines across Australia, South Africa, and America, showcasing its ability to navigate challenging terrains, accurately localise itself in complex environments, and provide 3D visualisation of surroundings.

The combination of Hovermap and Boston Dynamics Spot demonstrates the LiDAR scanner's versatility in various locations' and unlocks real value in post blast re-entries. Its real-time underground navigation capability, ability to map and monitor hazardous areas, and even assess post-earthquake scenarios makes it a powerful tool for data capture and decision making in potentially high-risk environments.

"One of the key advantages of this solution is its ability to conduct re-entry inspections remotely from the surface. By eliminating the need to send personnel into hazardous areas, it significantly reduces downtime and enhances safety protocols. The autonomous nature of the system ensures consistent and reliable inspections, contributing to improved operational efficiency and risk mitigation."

Beyond robots and unmanned aerial vehicles, Emesent is currently trialling deployment on boggers.

"Another emerging example is the integration of our Hovermap technology into underground boggers, forming a plug-and-play hazard detection and warning system. By seamlessly interfacing with the mining communication network, data from Hovermap are relayed to the surface in near real-time, empowering decision-makers with timely information," outlines Farid.

This integration could allow for timely scheduling updates, monitoring of remaining muck piles, and geotechnical assessment of open stopes to reduce risks associated with tele-remote boggers becoming buried.

Within just a few years into their commercial journey, Emesent has introduced multiple value-adding solutions beyond their initial drone-based offering, promising a bright and innovative future for this Australian-based digital solution provider.

Farid shares, "We are continuously improving and evolving our mining solution. We've recently added change detection and convergence monitoring capabilities into our data processing and visualisation software Aura. And we launched a mission planning and control app for pilot-assisted and autonomous mapping missions called Commander."