Replacing diesel fleets with alternative transportation methods is becoming an increasing priority within the mining industry. While diesel trucks are still in use, the adoption of battery electric vehicles (BEVs) is increasing. ABB is one of the global organisations at the heart of bringing the future all-electric mine into the present with its comprehensive eMine™ framework.

However, the rapid progress needed to decarbonise operations in line with global net zero targets isn't achievable in siloes. We spoke with ABB's global product line manager – electrification and composite plant Mehrzad Ashnagaran, head of global eMine™ solutions Nic Beutler, and global eMine™ sales manager from ABB Process Industries Ratna-Kanth Dittakavi to discuss why industry collaboration is critical for building the all-electric mine.

What challenges are mining organisations facing when looking to adopt electrification technologies?

One of the greatest electrification challenges faced by the mining industry today is the design of the mine itself. No one mining operation is the same. Every site has unique environmental and operational challenges, which means off-the-shelf solutions to adopt electrification won't work in the long run. For example, electrical infrastructure will differ from site to site. Many remote sites do not have access to a reliable and robust electrical grid. Fleet electrification solutions will result in a significant increase in power requiring access to a medium voltage (MV) distribution system which itself is connected upstream via a high voltage substation to the grid or to a microgrid which could, for example, also be supported by renewables. The design must consider where the closest location MV substation is for power and where a charging station can be installed. These considerations all need to be made based on the specifics of the mine operation.

Despite these challenges, we see the mining industry joining together to make sure we're all moving towards sustainable operations.

What joint progress has the industry made towards achieving the all-electric mine?

Only a few years ago, the conversation around collaborative, integrated electrification and automation initiatives was very siloed. However, the industry has made strides together to accelerate the adoption of electrification technologies.

Electric-driven equipment and electrical infrastructure are now being put in place in certain geographies – in Europe and North America, for example, where there is greater access to cleaner sources of energy. Moreover, the industry has reached a consensus that electric systems, combining automated elements, smart solutions, and interoperable, standardised interfaces, are the future. It will take time, but legislation and policies from governments are moving in the right direction to support electrification.

At its core, the ABB eMineTM approach embraces interoperability between infrastructure and electric vehicles along the three interface dimensions: electrical, mechanical and communication. ABB is also a founding member of the CharIN Mining Taskforce tackling the standardisation of the bespoke interface whilst leveraging the experience of the automotive industry. Ensuring interoperability and standardisation in energy delivery solutions for heavy transport and haul trucks is critical in accelerating the industry's adoption of battery-electric technologies onsite, reducing duplication in technology development, and developing a solution applicable to all major applications.

Collaboration is showing its value through the ‘Dynamic Charging Interface (DCI)' whitepaper and one under development for the ruggedised MCS (MegaWatt Charging System), an adaption of the automotive MCS solution. Furthermore, a subgroup focusing on X-MCS, the next even higher power connection interface solution, is well on its way.

Why is interoperability key to helping the industry navigate these challenges?

Real value for our customers comes from long-term partnerships. Customers worldwide often ask similar questions and face familiar electrification challenges. Typically, no single supplier has all the answers: joint efforts and problem-solving are essential. Every mine is unique, with distinct topography, infrastructure, minerals, and onsite expertise.

We believe no company can create the whole solution alone. Collaboration is key: some design the solution, while others implement and run it. We aim for our technology to be industry-agnostic and compatible with third-party infrastructure, such as control systems or mining truck charging stations.

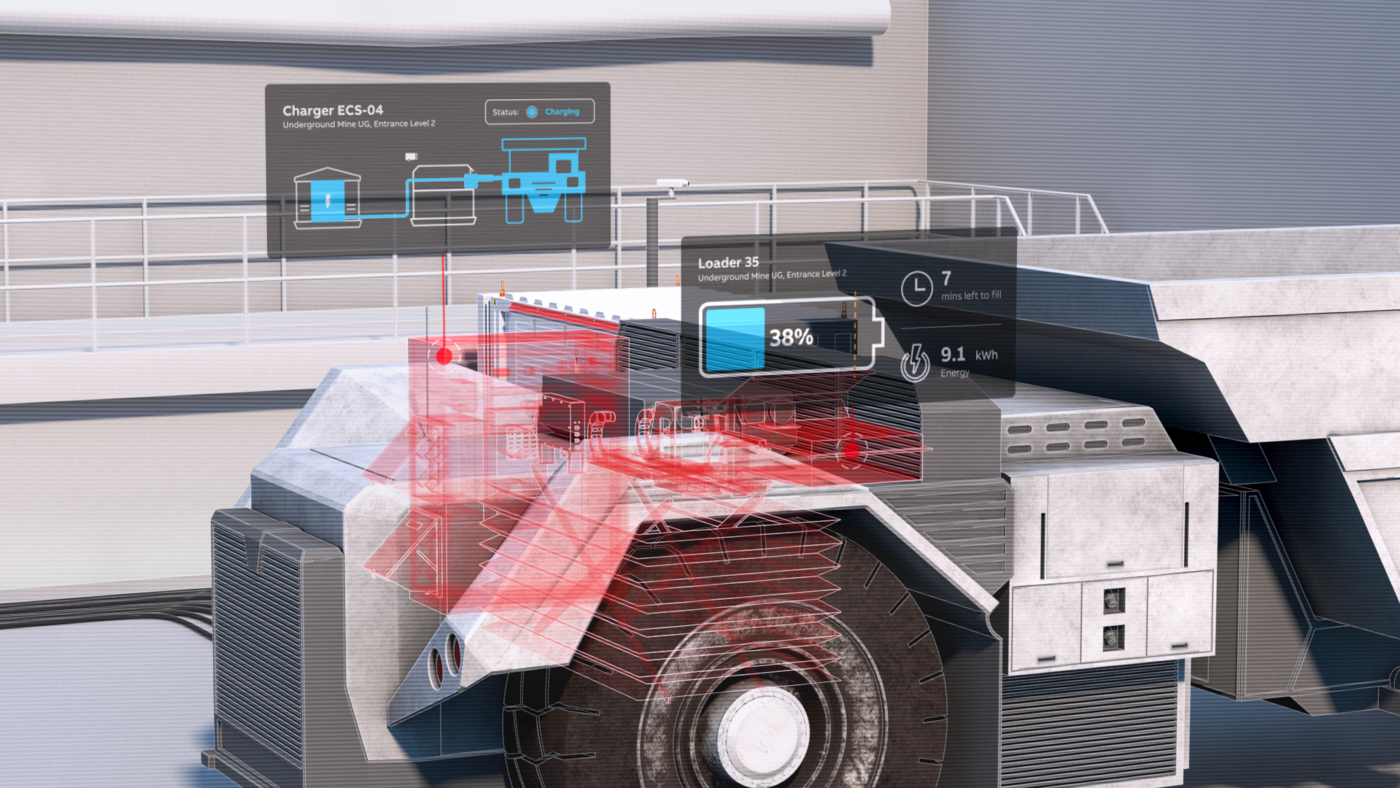

Interoperability and standardisation will reduce duplication in charging infrastructure globally. By collaborating, ABB can help define requirements and test interoperable energy delivery solutions in mining. These solutions include stationary systems like eMineTM FastCharge and dynamic systems like eMineTM Trolley. Together, we innovate energy delivery technologies to standardise the interface between infrastructure and electric vehicles for mining.

Can you share an example of a collaboration that has helped the industry take a step towards the all-electric mine?

A vital component in the transition to electric mines is a robust and reliable infrastructure, as every mine that moves to BEV fleets requires the technology to keep them running efficiently. Going further, as mines may be running various types of fleets, they shouldn't need a different infrastructure solution with proprietary interfaces for each.

Building on this, ABB's eMine™ FastCharge was created with interoperability at its heart. The FastCharge system itself was developed upon open standards, fully automated, ensuring it is compatible with third-party infrastructure and can be adopted into existing frameworks. It can be adapted to either pin and socket (ruggedised), megawatt charging system cables (manual or automated) or future interface solutions without disrupting communication and electrification interfaces, harmonising mechanical and electrical components. It can be counted on as a modular, high-power and interoperable engineered charging system solution for mining truck applications.

Industry collaboration was also crucial in the development of the eMine™ FastCharge solution. Our partners MEDATech and Stäubli contributed with essential expertise and key components to ensure that FastCharge became a viable solution for mines.

What role does automation play in the electrification of mining?

Beyond the infrastructure to enable the shift to electric, automation is one of the most important components in the electric mine. Mines need to integrate automation into the whole system to create a complete overview of what is happening across an operation. This level of automation cannot be biased towards technology vendors, instead, they must enable users to have a complete and holistic view of their mine operations. After all, a solid automation solution and application adoption as well as maturity is the foundation for higher-order digital systems.

eMine™ approaches automation and electrification from the outset. At its foundation is the ABB Ability™ System 800xA® distributed control system (DCS), designed and evolved over more than 20 years to seamlessly integrate with ABB and third-party infrastructure, including switchgear, transformers, motors, drives and a host of industry-specific technologies. Operators have myriad sources of information and insights to hand for efficient operations, including early alerts when equipment needs servicing, remote assistance and remote monitoring to ensure optimal performance across the entire mine.