In 2015, Barrick Gold produced approximately 6.12 million ounces of ore with more than 75% production coming from the Americas region. Their Goldstrike mine is the most prolific gold-mining district in the Western Hemisphere and includes the Betze-Post open-pit mine, a truck and shovel operation, and the Meikle and Rodeo underground mines. Ted Olsen-Tank described how the PI System enabled Barrick Gold to operate more efficiently while complying with strict environmental regulations.

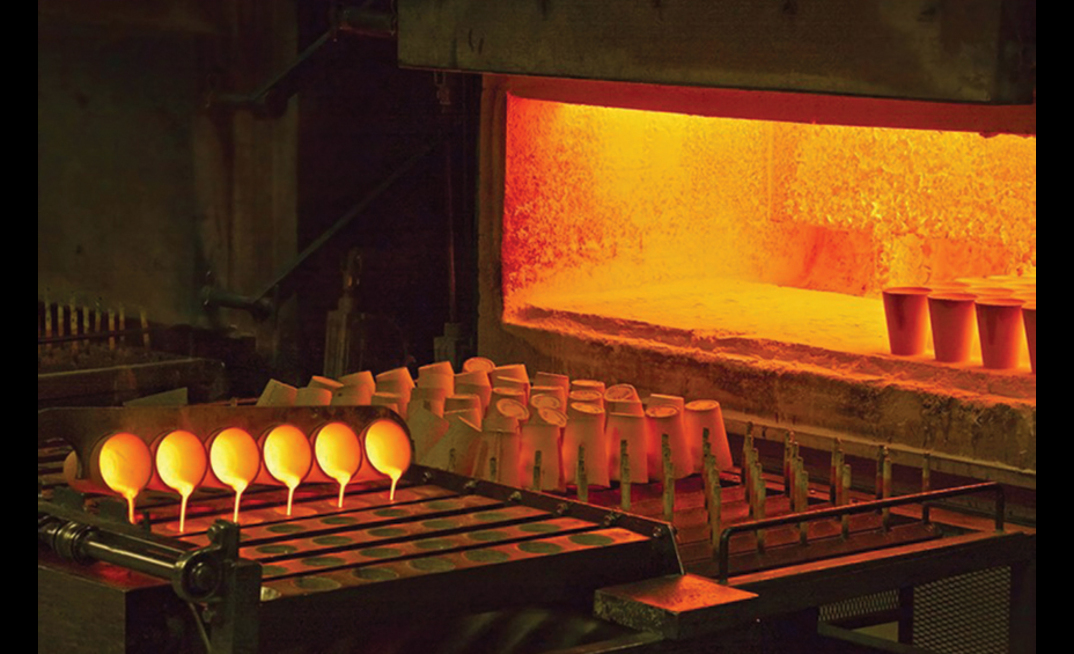

Olsen-Tank began by explaining why Goldstrike used the PI System to track environmental compliance. As the Goldstrike deposit went deeper and deeper over time, the composition of the gold ore changed. It contained increasing levels of total carbonaceous material (TCM) that preferentially adsorbs gold and gold cyanide complexes, making it more difficult to recover gold. Once stockpiles of low-TCM ore ran low, Barrick Gold initiated a $610 million capital project, the TCM Leach Project, to leach ore in the presence of thiosulfate and resin, not cyanide. The new system allowed Goldstrike to recover gold from material that was not usable before, but it brought with it a new set of challenges, particularly around environmental compliance.

Automating the Process

The TCM Leach Project built upon assets that were already in place. Olsen-Tank explained that the new thiosulfate resin process was "very complex compared to cyanide. There are numerous recirculating streams, each with their own complex sulfur-based chemistry." In addition, the expansion basically doubled the total equipment with minimal to no increase in operator manpower. Olsen-Tank relayed that the operators "were spread out over the additional circuits, learning new maintenance requirements for all the pumps, valves, pipes, fans, screens, etc." They were also responsible for design targets and monitoring temperature, pressure, concentration, pH throughout the new process. Ensuring environmental compliance while monitoring the new process was challenging.

Making the New System Meet Environmental Standards

For environmental compliance, Goldstrike's environmental group is responsible for all official record keeping and official reporting to state and federal agencies. Olsen-Tank said, "the official record keeping that environmental reports to the CUSTOMER PRESENTATION BRIEF As presented at the 2016 Users Conference Olsen-Tank, T., Environmental Compliance Monitoring at the Goldstrike Mine. OSIsoft.com. 4 April 2016. Web. 27 July 2016. CBBGGEN-072916b required agencies are put together from a web of interlinked Excel files. They've grown and evolved through the ages, and it just keeps building." He added that, "These records are put together days or weeks after the end of each month." The operations group was responsible for day-to-day environmental monitoring and reporting. Before the expansion project, operators who "had been running the circuits for 25 years knew in and out what [would cause a] permit deviation." Despite extensive training sessions on new system, "the operations group would find out weeks later from the environmental group when there had been deviations." As Olsen-Tank said, "Luckily, I was learning about the new advanced features in the PI System. So, I built something to do something about it."

To read the full story and learn how Barrick Gold achieved those results, please go to:

ABOUT THIS COMPANY

OSIsoft

HEAD OFFICE:

- San Leandro Tech Campus, 1600 Alvarado Street, San Leandro, CA 94577, USA

- Phone: +1.510.297.5800

- Fax: +1.510.357.8136

- Email: customerservice@osisoft.com

- Web: www.osisoft.com