Fine grinding using stirred milling is becoming more common in the mineral processing industry. Fine grinding allows liberation of the valuable mineral, which leads to higher mineral recoveries in the process plant.

The success of a fine grinding project can be strongly influenced by the energy efficiency, wear part consumption rate and maintenance intervals of the selected stirred milling technology.

The following presents some of the research work conducted on the Outotec HIGmill® grinding rotor design, and why the HIGmill is positioned as the most economical fine grinding mill type.

The Technology

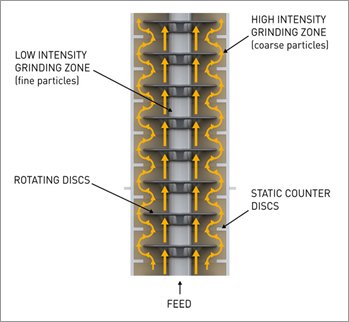

The HIGmill is a stirred mill, which has a stationary shell, with a rotating shaft and mixing elements to agitate the small diameter ceramic media. The slurry enters the bottom of the grinding chamber containing grinding media (beads) and rotating discs which provide momentum to stir the charge against a series of stationary counter discs.

The particles are ground by attrition between the beads. As the flow transfers upwards, the ore slurry passes through the rotating discs and the free space between the static counter discs lining the wall (see Figure 1). Due to the vertical arrangement of the mill, classification is conducted simultaneously throughout the grinding process with larger particles remaining longer at the peripheral, while smaller particles move upwards.

The process is typically a single pass with no external classification necessary. Gravity keeps the media compact during operation, ensuring high intensity inter-bead contact and efficient, even energy transfer throughout the volume.

Figure 1. HIGmill cross-section

Rotor Design

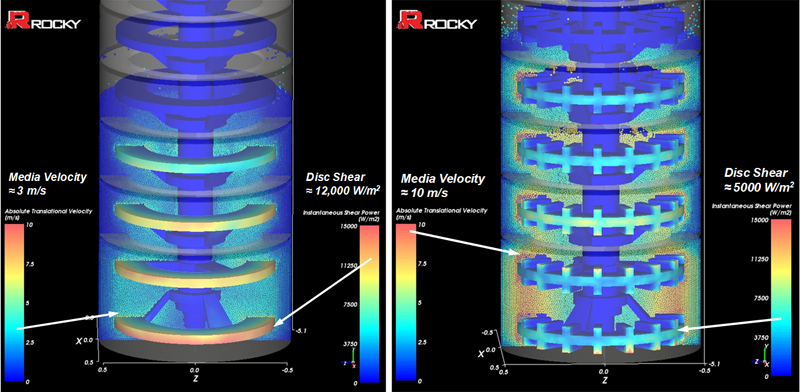

Discrete Element Modelling (DEM) was conducted by Outotec's inhouse modelling experts, to compare flat discs to Outotec's GrindForceTM rotors in a HIGmill. The grinding beads were found to be slipping on the flat disc surface and adding castellations to the disc reduced the slippage by holding autogenous layer of beads at the surface. Further to this, the castellated rotors forced more bead-to-bead shear further away from the rotors into the bulk of the bead volume, thereby more of the HIGmill's internal volume was used, increasing its apparent residence time. The difference in disc shear and media bed velocity is shown in the DEM models in figure 2.

One important outcome from this DEM work was that in order to generate the same power draw, the flat discs had to spin 2 to 3 times faster than the GrindForce rotors. This is reflected in rotor wear life, which was observed at a client's site, where the indicated flat disc wear life was ~1 month and the GrindForce rotor life is 6 to 8 months.

Figure 2. Flat discs: energy goes into disc wear; castellated rotors: energy goes into grinding.

Energy Efficiency

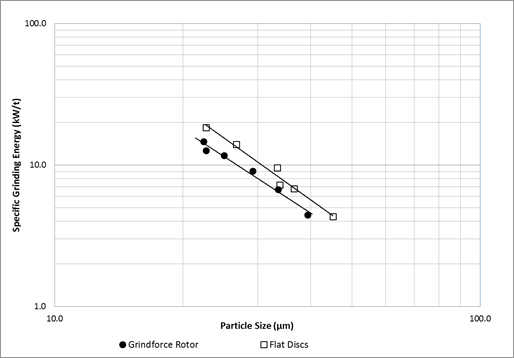

A large metalliferrous concentrator HIGmill was equipped with the flat discs. In order to improve efficiency of the power draw and prolong the life of the discs, GrindForce rotors were installed into the mill. Immediately after the installation of the castellated rotors, a benefit in the energy efficiency was observed. At the target grind size of 40µm, the required Specific Grinding Energy for flat discs is 22.7 kWh/t and for GrindForce rotors it is 16.3 kWh/t, a 28% energy saving. Recently Outotec has conducted rotor design optimisation work at the same site and achieved a further 5% decrease in energy use.

Further R&D testwork was conducted to compare the flat disc design against the GrindForce rotor design, using a different material under controlled testwork conditions in the HIG25 pilot scale mill. The GrindForce rotors gave 31% lower energy consumption than the flat discs for the 30µm target P80, as shown in Figure 3.

Figure 3. Specific Grinding Energy (kWh/t) versus the particle size (P80, µm) for the HIG25 Pilot Program, showing consistent reduction in energy consumption of approximately 30% for the GrindForce Rotor compared to flat discs.

Summary

Outotec HIGmills have proven industry performance and high grinding efficiency. DEM modelling has demonstrated that Outotec GrindForce rotor design prevents slippage of beads at the discs surface and produces more bead-to-bead shear away from the disc surface into the mill volume. Full-scale operations and pilot scale testwork have proven that the GrindForce rotor performance is far superior to flat discs in reducing energy consumption, decreasing wear part consumption and extending maintenance intervals. The patented GrindForce rotor enhances the industry leading HIGmill technology. For more information, please see our recent video of a HIGmill installation and commissioning for our customer in South Africa:

Or visit our webpage at http://www.outotec.com/HIGmill

ABOUT THIS COMPANY

Outotec

Outotec develops leading technologies and services for the sustainable use of Earth’s natural resources. Our 4,000 top experts are driven by each customer’s unique challenges across the world. Outotec's comprehensive offering creates the best value for our customers in the mining, metal, energy, and chemical industries.

HEAD OFFICE:

- Outotec Rauhalanpuisto 9, Espoo, FI-02230, Finland

- Phone: 35820529211

- Website: www.outotec.com