Today, when it comes to the exploration of mineral and raw materials in the mining industry, the measurement of the trajectory during drilling - both in the exploration phase and in production - is a key factor that those responsible for the geology, drilling, and planning departments must take into account. Even a slight error in the planning phase can result in the deviation of the well (or borehole), missing the final target body.

The main factors for the well trajectory being off-target are drilling parameters, the geological structure and the drilling method used.

Many companies and investors fund mineral deposit exploration projects that initially seem very promising. However, as they advance, the results do not always coincide with what was expected. One of the most common causes of this occurrence is the well trajectory missing the target during drilling the borehole. Likewise, the use of incorrect gyro survey technologies, combined with the lack of a robust quality control process used in the selection and operation of these tools, can also result in the well trajectory being off-target.

Further, the use of standard data synchronization programs in conventional systems often starts from the final data. In comparison, the technology implemented by Stockholm Precision tools (SPT AB) is based around a rigorous calibration control process for each tool, in addition to measurement checks that compare the In-Run & Out-Run data, which is then automatically processed by the SPT software. Stockholm Precision Tools is the only company in this field of exploration drilling, whose tools are equipped with this intensive quality control process, with the objective of protecting the client's investment.

When it comes to mining exploration, investors seek to obtain the best possible results from their mining projects, whether the target ore is present at the said location, or not. This provides them with the required returns to the capital they have invested for the mining project. Unfortunately, this is not always the case.

All too frequently, exploration projects overlook the importance of a Quality Assurance, Quality Control (QA/QC) Program for the positional survey data from the start. This is important because the data obtained from the geospatial location and the core sample in its exact origin are key to determine the existence or not, of the target mineral, on which the economic viability of the project heavily depends upon.

Advantages of using the correct gyro survey tool

An important factor that can affect the quality of a recovered core body sample is the wrong choice of the gyro survey tool, which is often chosen solely based on its price. A detailed analysis is needed around the question: What is more expensive: renting high-precision true north seeking gyros, such as SPT GyroMaster™ and Core Retriever™ (Fig. 1 and 2), or the incorrect evaluation of mineral reserves due to the use of a low cost and unreliable gyro survey tool?

Figure 1. GyroMaster™

Figure 2. Core Retriever™

SPT GyroMaster™: High accuracy True North Seeking Gyro Survey Tool

What is a Gyroscope?

The gyroscope is defined as an object that is in rotation, with two fundamental properties: gyroscopic inertia or "stiffness in space" and precession, which is the inclination of the axis at right angles to any force that tends to change the plane of rotation. These properties are inherent in all rotating bodies, including Earth.

Gyroscopic inertia and the force of gravity can be used to make the gyroscope function as a directional indicator or compass. If you consider a gyroscope mounted on the Earth's equator, with its axis of rotation located in the east-west plane, the gyroscope will continue to point in that direction as the Earth rotates from west to east. Thus, the eastern end will ascend relative to Earth, although it will continue to point in the same direction in space.

This resistance or compensation in force makes an opposing movement around the vertical axis, towards the meridian, so that the axis of the gyroscope always points to the true meridian (or to the true north).

Due to its operation being based on the rotational force of the Earth and not on magnetism, the GyroMaster™ has multiple applications and its use is increasingly widespread in geology and major mining exploration projects. The most important thing is to know how accurate the gyro survey tool that is being used in a project is. (Read more about fundamental principles of a gyroscope here)

The wrongly named Gyroscope - Reference Gyroscope vs True North Gyroscope

If we take a glance at different measuring equipment that uses gyroscope technology, different classifications such as the True North Gyroscope and the Reference Gyroscope can be seen.

The reference gyroscope lacks an accurate sensor that measures Earth's angular velocity projection; therefore, it is unable to find true north, which means it cannot find the azimuth. Before anything can be done, the collar azimuth needs to be introduced manually. It is not a gyroscope itself, but a reference or indirect measurement gyroscope (Inclinometer) and, of course, it is not a true gyroscope.

The inclinometer, as its name implies, is a tool that determines the inclination of a well and does not measure direction directly, but rather takes it from an external point and its data depends on the human factor, which causes the accumulation of errors as you go deeper into the well. It is important to note that the measurement of a tool is not only the inclination but is also the direction (azimuth). Since reference gyros lack the technology and sensors necessary to search for true north and establish azimuth, they do not have the capability to measure vertical wells/boreholes. You can find more information about the difference between a reference gyro, true north seeking gyro, and magnetic survey tool here.

Reference gyros are unable to measure vertical boreholes/wells

SPT GyroMaster™ is a true north seeking gyro survey tool, that can measure even with angles of +/- 90º. Its operation and accuracy have been proven in extreme conditions. In exploration wells that are in close proximity to each other or in complex reservoirs where precision is an essential requirement, the GyroMaster™ has been the key to the success of the project.

Risks of using Reference Gyro Survey Tools in Mining Exploration

The use of reference gyro survey tools in extremely important mining projects carries serious risks because their operation depends on human input. If the tool is supplied with the wrong starting data, the geology department risks falsely believing that they have found a low mineral reserve. It is the same case with other gyro survey tools that are true north seeking gyros but are not capable of repeating the measurement data during the descent to the well and the subsequent rise. That is why we have classified them as true north gyroscopes, but with low precision.

Initial reference values in reference tools are sometimes obtained using a magnetic compass - increasing the chances of errors

The use of reference gyro survey tools in mining exploration is as inaccurate as the use of low precision north finders.

Low precision gyros are very similar to the reference survey tools. Many times, they even obtain the initial reference point through a magnetic compass. Furthermore, because their method of operation is a single shot, they do not have the ability to measure continuously, these tools tend to accumulate errors between each measurement interval.

Evaluation of mineral reserves depends on the measurement of the trajectory

Stockholm Precision Tools (SPT ) is proud to have specialized in the development and manufacturing of high-precision gyro technology for more than 20 years such as the GyroMaster™ for the mining sector; the GyroTracer™, for oil and gas; and, most recently, the Core Retriever™, which is capable of simultaneously taking measurements and recovering cores. The precision data of Stockholm Precision tools in inclination is 0.05º, unlike the value offered by other manufacturers whose equipment works with a calibration that allows an error of 0.3º, which results in the constant inaccuracy of the spatial position of the well. If we add the real deviation to this, the magnitude of the error can be 6 to 10 meters, depending on the depth and inclination of the well: the greater the inclination, the greater the projection, and therefore, the geology department will obtain incorrect data.

The main driver for writing this article is to highlight the importance of using the correct gyro technology together with a rigorous quality control process during the operation to avoid the many errors we have seen in the industry for calculating reserves that have arisen as a result of using low-quality tools with no quality control process.

Tools with an accuracy of 0.3 can be up to 6 - 10 meters off target. The greater the inclination, the greater the projection.

Let us take, for example, an ore body which is 5 meters wide with a dip of about 45º and a depth of 1000 meters. If we use a tool whose specifications contemplate a margin of error of 0.3º in the inclination and several degrees in the azimuth, the possibilities of erroneous calculations on the dimensions of the mining body will be high. Therefore, the probability of under-reporting the presence of minerals will be high too and the subsequent effect on the mining company's investments could be negatively affected.

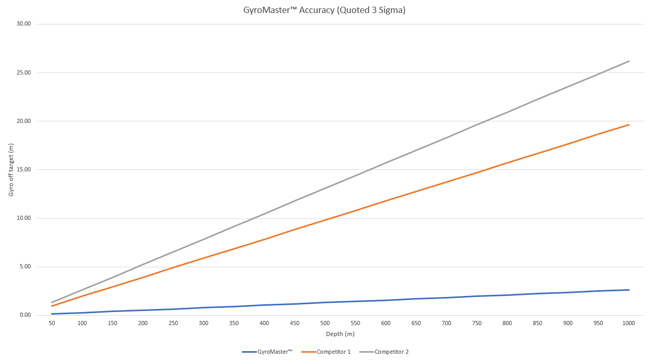

The following table (Fig. 3) gathers the data and technical specifications of different tools, taken from the websites of their respective manufacturers. Here the error in the final coordinates is evident. Drill trajectory measurement with the use of the GyroMaster™ true north seeking reduces this error to a minimum; showing, with real data, that Stockholm Precision Tools is the leader in quality control of trajectory measurement.

Figure 3. Accuracy of the GyroMaster™, comparing with other tools in the market

Quality Control in Mineral Exploration

In addition to the risks that we have already mentioned with the use of a low-precision north-seeking gyroscope or a reference gyroscope, there is another concerning factor. This is that those who decide to use these tools in their projects do not always have the mechanism or technology to verify that the value of 0.3º of precision in the inclination, coincides with the reality of the measurement. Many times, it tends to be higher, not to mention the obscure azimuth or direction accuracies stated.

When it comes to quality control and quality assurance in using gyro technology for mining exploration projects, Stockholm Precision Tools (SPT AB) has implemented a rigorous model, (see Fig. 4) of controlled checks and audits, making it one of the few companies who have developed and implemented a Quality Assurance and Quality Control (QA/QC) process. This process can be seen in both borehole trajectory measurement and measurement during core recovery in B, N, H, P holes.

Understanding the risk for investors of often having millions of dollars invested in mining projects and the devastating effect that this environment of errors caused by the lack of information can have, we are continually ensuring the quality control of our tools and process. Proof of this is also our Gyro RigAligner™, a compact and lightweight tool that looks for True North, and aligns the rig platform in less than 5 minutes. It is also the only 3-axis aligner that works in all directions (vertical, horizontal, and inclined).

Fig. 4. Quality Control Process implemented by Stockholm Precision Tools (SPT AB)

Ways to Check the Accuracy of a North Seeking Gyro Survey Tool

There are several methods to check the accuracy of a true north gyroscope or north-seeking gyro, the most effective being the measurement in a deep well (about 1000 meters approximately) and the subsequent comparison between the values of the In-Run & Out-Run. In addition, the initial data is verified by the topography department.

Another way to check the precision of a tool is to have a calibration stand, such as the Universal Calibration Stand CF.02 (Fig. 5), designed to work with SPT tools.

Fig. 5. SPT Calibration Stand

In other cases, the manufacturer should be required to show the ability to measure vertically, i.e. -89 degrees in continuous mode, and to demonstrate that both down and up values must not exceed 0.15% in the coordinate NS / EW.

Let's explain this in more detail: before selecting the gyroscope to be implemented in a project, In-Run & Out-Run measurements must be made to verify that the azimuth and inclination data are repeated according to the specifications declared by the manufacturer. Both measurements must be evaluated, and the data must be the same. It is the best way to check the quality of the tool, moreover, these measurements should be made in different inclinations and directions.

Finally, the tool should be tested under harsh environmental conditions. If that opportunity does not exist, it can appeal to the topography department to use the calibration stand to calibrate the gyro tool.

The main problem we have detected in our analysis is the lack of a reliable quality control standard for well trajectory measuring technologies globally and that the client is often guided by published specifications, by the ease of use, low prices, or by other factors unrelated to the precision of the tool. Consequently, this can lead to erroneous decision making and financial losses for investors, which could have been easily avoided.

ABOUT THIS COMPANY

Stockholm Precision Tools

Stockholm Precision Tools (SPT) has been designing downhole solid-state survey tools and supplies for the world’s major oil, gas, mining, and civil engineering companies for over 20 years.

HEAD OFFICE:

- Domherrevägen 11, 19255 Sollentuna, Sweden

- Telephone: +46 (8) 590 733 10

- Web: sptab.com