International miners and explorers are looking for advanced technology to overcome the challenges brought to light by COVID-19.

Lockdowns and physical-distancing measures have impacted many workforces, and the knock-on effect of resource and supply disruption, has highlighted weak spots in the global mining and exploration industry's resilience.

The impact has varied between different countries, commodities and mine sites. Countries such as Australia are experiencing limited impact within closed borders, while restrictions and impacts in others, such as South Africa and Brazil, have witnessed severe lockdown measures significantly affect mine production.

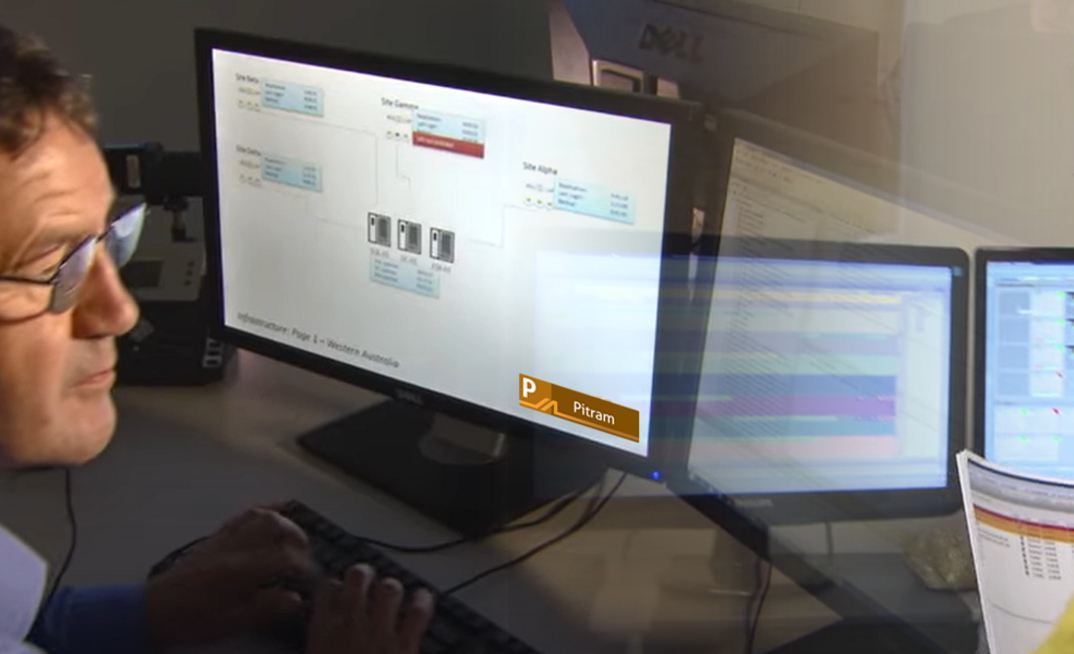

As the industry looks towards more automated practices, demand is growing for MICROMINE's Pitram fleet management and mine control solution.

Pitram records data related to equipment, personnel and materials, providing an overall view of current mine status and enabling improved control over operations to boost production, reduce costs, and improve safety and business intelligence.

The mine control solution of choice for more than 50 mining operations across the globe, Pitram can be deployed remotely, with training and support offered by MICROMINE's product specialists via telecommunication and digital channels.

"Many of the practices in the mining industry have been turned upside down by COVID. Domestic and international travel is at a standstill and as a result the face-to-face interactions that have been relied upon have also been affected," said Pitram Product Strategy Manager, Chris Higgins.

"So while miners large and small have had to grapple with finding new ways to do business, one thing they haven't had to do is worry about how they can deploy Pitram onsite when a member of MICROMINE's team can't physically be there."

"At MICROMINE we appreciate that while our clients are usually technically savvy, integrating and deploying new systems can cause disruption if not handled efficiently. That's where our specialist technical team and advanced training comes into its own."

MICROMINE has completed numerous successful remote deployments for scoping studies, installations and training for global mining operations including projects which cross continents and users with multiple languages.

As an example, Pitram has just been deployed remotely at a gold mine in Greece. Without the need for Pitram specialists to be on-site, the miner has been able to expedite the implementation of the solution. This has been made possible through extensive training offered by MICROMINE. Personnel at the project have received 86 hours of online training and 47 hours of online Go-Live coaching to enable them to competently and effectively use the Pitram modules.

"As these virtual meetings are often recorded, the client is able to use the training sessions to get all of its crews up to speed on the decisions made, train new personnel and use it as an auditing tool," Mr Higgins said.

The Greek mine is just one of many Pitram clients taking advantage of MICROMINE's tailored online sessions which can provide a more targeted and less disruptive form of focussed training than the traditional face-to-face onsite workshops.

For more information visit www.micromine.com.au.

ABOUT THIS COMPANY

Micromine

MICROMINE is a leading provider of innovative software solutions that span the breadth of the mining cycle from geological exploration and data management, to resource estimation, 3D mine design, planning and production control.

CORPORATE HEAD OFFICE:

- Perth, Australia Level 2, 174 Hampden Road, Nedlands 6009, Australia

- Phone: +61 8 9423 900

- Fax: +61 8 9423 9001

- Email: marketing@micromine.com

- Web: www.micromine.com