Portable X-ray fluorescence (pXRF) analysers have become an important part of the exploration geologist's toolkit over the past 20 years, and innovation around the application of this technology in mineral exploration continues apace.

Manufacturers have focused on improving detector technology, instrument stability, heat resistance and data connectivity in an attempt to ruggedise and modernise the latest versions of these instruments. pXRFs are now capable of measuring up to 35 elements between Mg and U on the periodic table with some elements measuring down to 1 part per million.

One of the main reasons pXRF contributes to better discovery rates is that it allows companies to conduct fast, effective field sampling at the early exploration stage, according to Todd Houlahan, Director of International Mining at Olympus.

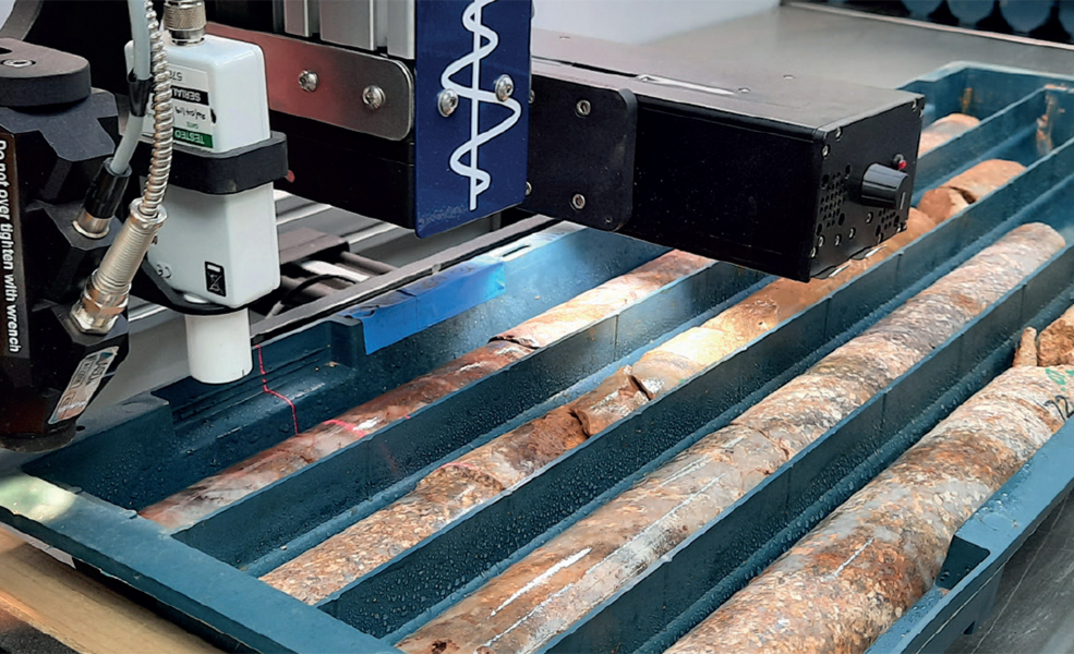

Olympus Vanta pXRF analyzing RC samples in the field

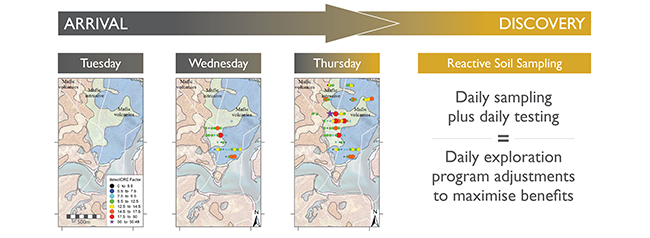

"Use of portable XRF enables quantitative analysis of a large number of samples in the field and adaptation of sampling programmes in real time. Portable XRF assists explorers in focusing their activities on more prospective areas within a tenement and on more prospective zones within a drill hole," Houlahan says.

To give a recent example, an Olympus pXRF analyser contributed to the discovery of Cobre Limited's Perrinvale Project, a VHMS deposit enriched in high-grade copper, silver, gold and zinc in Western Australia's Goldfields region. This area is mainly known for its gold prospectivity but pXRF identification of copper, zinc and silver mineralisation within sulphides at surface led to intensive follow up and subsequent drilling success.

The other main benefit to pXRF is the cost savings, with most users reporting a return on investment within three to six months, according to Houlahan. Listed explorers have reported hundreds of thousands of dollars in savings using pXRF by limiting the number of holes requiring re-drilling due to calling the end of holes too early, through optimised fieldwork and rapid follow up, and through a reduction in samples sent to the laboratory. More efficient and intelligent use of exploration budgets should decrease the time to discovery.

Olympus portable XRFs have advanced to the point where their effectiveness is now highly dependent on three factors unrelated to the instrument hardware: 1) the person operating it; 2) the workflow; and 3) the sample type being analysed. The ideal sample type is one that has been pulverised into a fine pulp, according to Houlahan. However, XRF's portability is such that people want to test any and all types of non-homogenous samples. As a result, success depends on developing a "fit-for-purpose methodology."

In a paper published in Geochemistry: Exploration, Environment, Analysis in 2019, a team from the Centre of Ore Deposit and Earth Sciences at Australia's University of Tasmania described a study of pulp powders and rock slabs from six porphyry districts (Yerrington - Nevada, US; Resolution - Arizona, US; Las Bambas - Peru; and Cadia, Northparkes and Cowal - all in New South Wales, Australia). After calibration of their Vanta pXRF using whole-rock laboratory data, the team concluded that pXRF data can be used in place of conventional whole-rock analytical data to inform strontium/ yttrium and strontium/manganese oxide copper-prospectivity discrimination diagrams.

Work was done to demonstrate a fit-for-purpose methodology directly on fine, medium and coarse-grained rock slabs. The team found that collecting three spot analyses from the coarse sample at random was sufficient to overcome the intrinsic heterogeneity of the sample and provide useful information about copper fertility.

In collaboration with Olympus, several third-party companies are addressing how best to deal with sample heterogeneity in multiple and contrasting ways.

Meffa Lab Oy and Geotek are integrating Olympus pXRFs into automated sample and core scanning systems to allow intensive multi-point analysis of samples to "average out" the heterogeneity in drill core using pXRF. To create more homogenous samples, Onscite and Imdex have designed field-based sample preparation tools-such as crushers, mills and presses-specifically for pXRF.

Additionally, Imdex has developed a solution that allows the user to operate the Olympus pXRF, force a QA/QC component into the workflow, securely transfer field-validated data to the cloud, and apply advanced data analytics to pXRF data. This is the first offering that attempts to address the three biggest variables associated with pXRF use (the user, the workflow and the sample) in one end-to-end package.

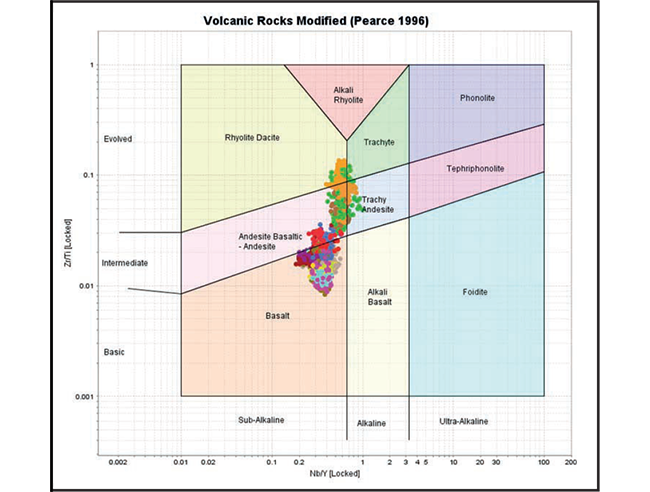

Lithological discrimination in ioGAS using Vanta pXRF

Imdex's In Field Geoanalysis Solution

Commodity-specific innovation in pXRF has largely focused around cobalt, lithium and gold. As elemental lithium is too light for any pXRF to measure, the application of pXRF to lithium deposits has focused on pathfinder elements. The main focus has been on potassium/rubidium ratios, a potential indicator of lithium prospectivity in pegmatites.

Cobalt mineralisation is often associated with the presence of iron and/or nickel, with the presence of both these elements having a detrimental impact on the ability to accurately measure cobalt with pXRF. Fortunately, advances have been made in algorithms which have now demonstrated pXRF can be used more effectively on cobalt at concentrations less than 0.05%, a particular area of interest for cobalt explorers.

Like cobalt, gold can occur in spectrally complex matrices, making it difficult to measure with a pXRF at the low concentrations typically required. However, gold explorers make a up a large part of the global pXRF customer base using the technology for lithogeochemistry and chemostratigraphy to better understand the geological system being investigated and by identifying pathfinder elements (e.g. As, Cu, Pb, Zn, Bi, Hg, W) to vector towards gold.

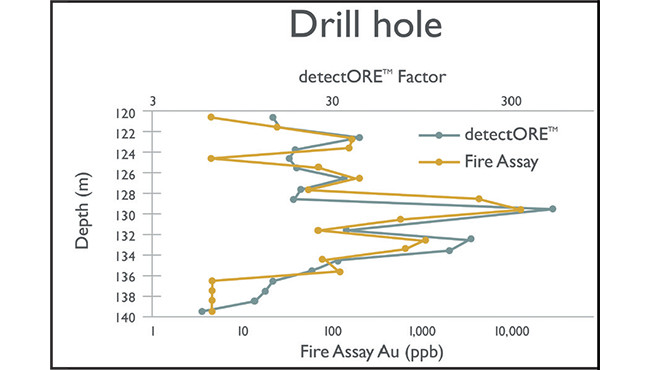

Houlahan points to Australia's Commonwealth Scientific and Industrial Research Organisation's (CSIRO's) patented and trademarked detectORE technology as "a particularly exciting development for gold." DetectORE combines a consumable, a pXRF and customised software, aiming to quantify Au down to below 20 parts per billion within eight hours of sample collection. Perth-based Portable PPB holds the exclusive licensing rights to this invention. Houlahan says that with a proven management team, an impressive list of companies signed up as industry partners/sponsors and several years of global R&D under their belt, "they may just be on the cusp of achieving the holy grail" — low-level gold detection with pXRF.

Case Study data illustrating the value proposition of adoption of the Portable PPB process

Drill hole data showing detectORE results versus fire assay

ABOUT THIS COMPANY

Olympus

Olympus is a leading manufacturer of test and measurement solutions used in applications including aerospace, oil & gas, infrastructure, and automotive.

HEAD OFFICE:

- 48 Woerd Ave #102, Waltham, MA, 02453, United States

- Web: www.olympus-ims.com

- Email: info@olympusNDT.com

- Tel: 17814193900