Autonomous drone mapping technology developed by Queensland-based tech company Emesent is being used around the world to help underground mining operations inspect stopes, raises, drives - essentially any underground or above ground void.

Launched in January 2019, Hovermap is a smart mobile scanning unit that combines light detection and ranging (LiDAR) mapping with real-time 3D simultaneous localisation and mapping (SLAM) and advanced autonomy technologies for autonomous beyond-line-of-sight drone flight.

Hovermap has changed the way underground mines conduct inspections and monitor deformation.

Remote Inspections Improve Safety

Using traditional cavity monitoring systems (CMS), surveyors used to scan stopes from a mid or overcut, potentially exposing them to hazards associated with open voids and delaying production.

Hovermap keeps personnel away from hazards because it can be attached to a drone and flown into a stope to capture a detailed 3D model. This model is then used by surveyors, mine and geotechnical engineers to accurately identify geotechnical features that may impact stope performance and reconciliation.

Many mines inspect a stope after each blast to assess blast performance to design and identify potential geotechnical issues.

A technical services manager at a North American mine describes how they rely on the data Hovermap provides.

"We need to deal with a rock mass in a high stress environment. When stopes start to overbreak we want to know whether it is in an area that could compromise access, and if we continue to muck, what the impact is to overall stope performance," he said.

"Our mining rate is obviously impacted if we get oversize material coming in. So being able to actually see the fault planes in a stope helps us determine whether we're going to be fighting this for months or it's just one zone that's fallen in," he said.

He said they are now able to make informed decisions of whether to keep mining.

Hovermap is also used in fall-of-ground situations, ensuring areas can be mapped quickly and safely.

Swedish miner LKAB engaged local remote sensing specialist AMKVO AB to map the massive Kiruna iron ore mine with Hovermap after a seismic event in May 2020.

AMKVO AB produced a comprehensive damage assessment by flying Hovermap at a depth 1236 meters below the surface. They completed 30 scans in four days to map kilometres of damage in challenging conditions, navigating the drone around collapsed services, ventilation bags, and rock falls.

Previously, damage from seismic events had been mapped using ground-based methods. AMKVO AB CEO Alexander Paulusson said they were able to scan much faster than LKAB expected. "Nearly all the areas LKAB had identified for inspection were scanned on the first day," he said.

"We were quick, way quicker than they expected."

LKAB section manager for sublevel caving Per Brännman said the drone was a good tool, but the scanner [Hovermap] was truly revolutionary.

"Safety must always come first. This is a safe and efficient way to work. Material from the drone flights is already being analysed, which means that damage surveys can be done more efficiently, more safely and faster than before. In terms of safety and technology, the use of drones and scanners represents a major step forward," he said.

Hovermap Advantage

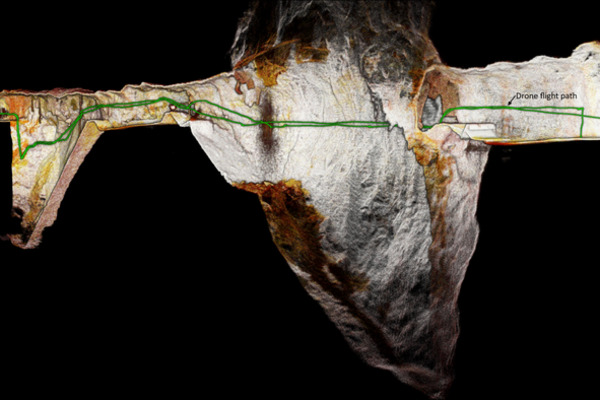

Hovermaps' advanced SLAM algorithms enable mobile mapping and autonomous drone flight even when GPS is unavailable. Its in-built multi-channel LiDAR sensor rotates to capture a 360˚ x 360˚ field-of-view scene, which is processed on-board in real-time to stream a 3D map to the operator.

Pilots can interact and explore the scan data to deliver the results they need. They can fully explore the target area by quickly and easily setting waypoints on the 3D map. The advanced autonomy capabilities mean that Hovermap navigates around obstacles and through gaps to reach the waypoints and complete the data capture.

The Hovermap technology includes advanced fail-safes and behaviours to deal with underground conditions, such as dust, thin wires, and Wi-Fi loss.

Rapid Return on Investment

The Emesent Hovermap helps mines digitise their assets, including production quantities, stope surveys, drive deformation monitoring, pre-and post-blast inspections, and vertical shaft. Hovermap can be attached to a drone, a vehicle or a backpack, or lowered in a cage—maximising its use throughout a mine site.

"Some of the specific use cases for Hovermap are stope scan, you can do shaft inspections, stockpile surveys, pre- and post-blast inspections, shotcrete thickness analysis as well any anything else that you need to digitise around the mine, said Andrew Rouse, CEO of Digital Terrain.

The resultant point cloud data is in industry standard formats that can then be imported into existing mine survey, CAD and planning software, such as Deswik and Maptek.

Hovermap is now being used by surveyors and engineers in underground and surface mines in 17 countries, with miners integrating the Hovermap data capture processes into their operational workflows.

Safety and Savings

At BHP's Olympic Dam mine in South Australia, Hovermap's autonomous flight capabilities allow the site to safely capture data in stopes, drives, ore passes and decommissioned infrastructure.

Olympic Dam principal geotechnical engineer Evan Jones said just about every blast packet is now scanned, along with in-stope stock volumes.

"Geotech is using it for stability analysis and reviewing each of the scans that come through, and over-break and under-break are being calculated at a higher resolution than was done previously," he said.

The technology is helping improve underground mining operations by increasing efficiency and safety.

British miner Petra Diamonds said it saved millions by using Hovermap to scan ore passes at one of its African mines.

Petra group strategic business and innovation manager Alex Holder said Hovermap was lowered down an ore pass scheduled for rehabilitation.

"The visualisation delivered exceeded all our expectations," he said.

"The data captured in one ore pass saved us significant time and effort by confirming it was irreparable and that saved us millions."

Holder said the ability to switch the Hovermap payload between the various applications meant that they were able to scan a considerable amount of the mine in one shift.

ABOUT THIS COMPANY

Emesent

Emesent is a world-leader in drone autonomy, LiDAR mapping, and data analytics. Emesent has built a reputation for delivering high-quality data capture in the mining, infrastructure, survey and mapping industries.

HEAD OFFICE:

- Address: 40-52 McDougall Street, Kings Row Office Park, Level G, Building 4, Milton, QLD, 4064

- Tel: 61735489494

- Website: https://www.emesent.io/