Epiroc's strategy to support mining companies on digitalisation journeys has evolved rapidly over the past year, with the Swedish original vehicle manufacturer (OEM) stepping up its acquisitions of technology firms that bolster the already robust portfolio in its Digital Solutions division.

Some 11 acquisition moves were launched over the past 12 months, representing an investment of SK1.2 billion (US$109 million). But these were dominated by companies that brought something important to the digitalisation table.

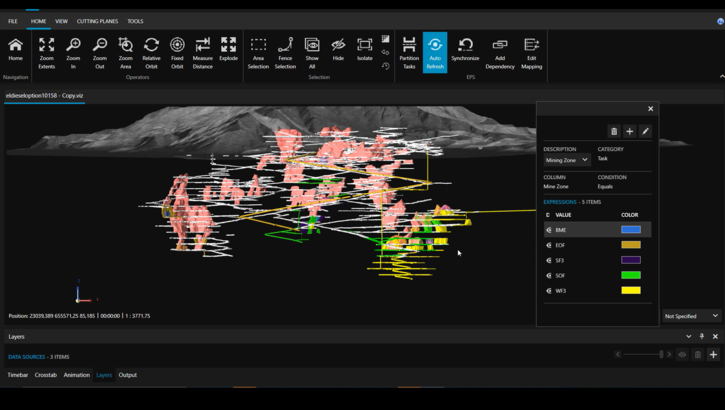

MineRP, for instance, is a software company that specialises in increasing productivity for mines through integrated planning, execution and analytics. Epiroc also acquired the remaining share of Mobilaris MCE, which provides advanced situational awareness solutions that optimise operations.

Mikael Ramström, vice president of digital business, said that the acquisition strategy is shaped by the company's trailblazing involvement in digitalisation from the ground floor - from when the phrase wasn't even used in a mining context.

"Interoperability and collaboration have been key initiatives since the early 2000s. We were heavily involved in one of the first initiatives in this area, when mining companies and machines suppliers found that we needed to standardise data exchange between assets," he said.

"Since then, we have pushed hard on this, and if you look into our major investments or acquisitions in digitalisation, that area of interoperability was the first step.

"MineRP, for instance, has an enterprise integration solution that helps our customers to integrate - that's the interoperability part - what they already have. We don't come in and replace [assets] the customer has already invested in, but we help them to integrate better

Interoperability is in our genes

"On the other hand, Mobilaris focuses a lot on safety and productivity, and this starts with the positional information that you can pick up from your infrastructure, and you complement this with your production data, so customers use their assets in a much more optimal way - as well as have full control over all their assets in an emergency, such as a fire or where you have to evacuate your mine."

Customer-centred

Ramström noted that the company's strong roots in the history of digitalisation give it an edge in terms of designing customer-focused strategies - whether the project is large or small, and whether the miner is at the start or the middle of a digitalisation journey.

"Epiroc has experience with both huge and minor projects. We sit down with the customer and talk through what are the priorities for them. What is it that they want to focus on? Is it productivity? Is it safety? Is it sustainability?" Ramström said.

"With digitalisation, it is good to take small steps to identify infrastructure needs, so that you start in the right way, and that is our approach."

Ramström said that his company had taken a hard look at the state of analogue versus digital-ready infrastructure in the mining market, and the results were, perhaps, surprising.

"Epiroc has been looking at which customers have the infrastructure that can be converted to digital in a short time frame, and the answer is, it's relatively few.

"Up to less than a quarter of the customers are ready now. So, we have to start with investment in the infrastructure, looking at what assets are smart already, and what progress you can make with the other assets to make them a little smarter".

ESG enabler

"Then how will all this plug into your datamanagement system? Then after that, only then can you start to deliver value in digitalisation."

The challenge is considerable, but he noted that digitalisation would be critical in miners' meeting their ESG objectives.

According to consultancy McKinsey, the mining industry is currently responsible for 4-7% of global greenhouse-gas emissions. But in 2021, the world's top miners, including Anglo American, Rio Tinto and BHP, all committed to a goal of net-zero direct and indirect carbon emissions by 2050 or sooner.

"We see that digitalisation as an enabler or a precondition to achieving those ESG objectives," Ramström said.

"You might think that reducing carbon dioxide, energy use, water use and pollution, and so on, is your focus when working with ESG - and also, being careful about using or overusing your assets.

"But you are working blind if you don't have digitalisation to give you insights around all these factors. Without correct and updated information, this blindness leads to promises made without value.

"What Epiroc is doing and what we have, for instance, with the MineRP solutions, is creating actual tools where you can plan, where you can monitor, optimise and deliver on these ESG objectives."

Structured approach

This ESG-focused strategy has been central to a digitalisation plan that rests on the company's historical role as an OEM.

"We are an OEM supplier to our customers. And if you start on that, like a pyramid, all these assets are already smart - we have been working on this since the late 1990s, when we introduced computers into all these machines," Ramström said.

"We worked with integration and interoperability since the early 2000s. It's not until, like, 2015 that the industry took off in this, but we were prepared, we were waiting, and we were eager to supply.

"During that period, we developed solutions built on machine data, where you make the information and data available to the customers from the Epiroc intelligent machines.

"Now, this is not limited to only our machines. Now with MineRP, we can integrate all types of devices because of the interoperability - this is in our genes.

"Adding to that, but investing in Mobilaris, we have added more machine information, positional data and time aspects, so that you now have a complete view of your assets in the mine.

"And now it's not just Epiroc; it's all assets in the mine you can track with this. You're more efficient in your operation.

"The next step up in the pyramid that can be taken with MineRP does not include [only] the classic assets that Epiroc and other OEMs work with, but also the process and planning data, and all these come together into the minority solutions.

"So for us, it is a layered approach. This approach enables us to partner with customers in digitalisation in the same way we are a partner in mechanisation, automation and electrification.

ABOUT THIS COMPANY

Epiroc

Epiroc is a vital part of a sustainable society and a global productivity partner for mining and infrastructure customers.

HEAD OFFICE:

- Address: Sickla Industriväg 19, SE - 131 54, Nacka, Sweden

- Tel: +46 10 755 00 00

- Email: ir@epiroc.com

- Website: https://www.epirocgroup.com/en