Glencore Kidd Operations is a leader in mining technology adoption and recently launched a geological mapping project in collaboration with RockMass Technologies. Historically, the mine site had adopted a traditional pen and paper approach to underground mapping.

In this project however, underground data collection would be done digitally with the RockMass Mapper and automatically integrated into a 3D structural model. Six major faults were identified and mapped during this study, with a total of 20 mapped faces over a four-hour period. Overall, this is equivalent to approximately 12 minutes per face. The RockMass Lithos mapping software captures georeferenced true colour point clouds, .dxf annotations (CAD compatible) for all mapped features, and .csv structural orientations for each mapped face. The .csv structural orientations were the focus of this study as they can be easily imported as georeferenced planar structural discs into third party software.

The Problem

• Structural mapping and data integration into third party modelling software is often a tedious and time-consuming process

• Many structural models are left out of date, redundant or even missing critical information

The Approach

• Using the RockMass Mapper as a digital mapping tool in conjunction with Leapfrog Geo to improve efficiency and data accuracy by automating the underground structural mapping and 3D modelling workflow

• Map 6 major structures and 20 faces using the RockMass Mapper within a single underground tour

The Solution

This study offers a simple and efficient field-to-office mapping workflow that requires no manual data entry or postprocessing, and that promotes easy integration with third-party modelling software to generate 3D fault triangulations

The Workflow

The results

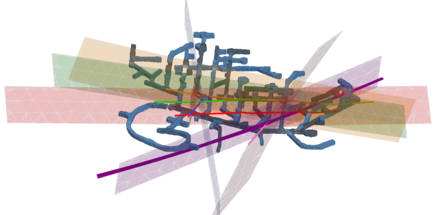

The estimated dip and dip direction of the estimated triangulations of the major faults were compared against existing structural mapping data to assess the accuracy of the predicted results. The image below shows the Leapfrog Geo model with both the estimated major fault triangulations and the existing major fault traces.

In the cases where a major fault was only mapped in one location, the dip direction of the modelled structure was approximately 13-20 degrees off from the existing mapped feature. When mapped in two locations, or in greater than three, the modelled results displayed a dip direction variation of about 10 degrees or less, respectively- a 30-100% improvement in accuracy.

Want to read the full story?

Learn more about the Kid Creek mapping project and their results in the whitepaper: Connecting the dots between in-field data collection and structural modelling solutions. Receive the full whitepaper straight to your inbox and see how your mine site can benefit from an innovative approach to geological mapping.

ABOUT THIS COMPANY

ROCKMASS

Industry leading geotechnical and geological data automation solutions.

HEAD OFFICE:

- Address:111 Queen Street East, Suite 210, Toronto, ON, M5C 1S1, Canada

- Tel: 6472890997

- Website: https://www.rockmasstech.com/