The Companhia de Ferro Ligas da Bahia (Ferbasa) is located in Ipueira, a municipality in the state of Bahia in the northeast of Brazil. Ferbasa operates one of the largest chromite mines in Brazil and is considered a pioneer in the use of sensor-based sorting (SBS) technology. The company processes chromite obtained from an underground mine. The extracted material is pre-concentrated using sorting technology that employs sensors, and is later used in the production of specialized steel alloys. With a processing capacity of 12,000,000 tonnes per year, the company has been using sensor-based sorting for 10 years, in a completely dry process that separates waste from high-grade chromite.

Eriberto Nascimento Leite, Mining Director at Ferbasa, is a firm believer in this "new" technology, which is actually not new at all. The technology is already familiar to those who have had X-rays or travelled through airport security. However, this is a technology that was completely new to the mining sector 10 years ago. Eriberto explains that SBS technology makes all the difference for Ferbasa; it allows the company to avoid unnecessary processing by separating a fraction of the high-grade material from the metallurgical process feed in advance.

The benefit of this, is removing the requirement for any additional processing. In that way, particles which are not economically viable are eliminated from the process beforehand. This process is referred to as Pre-Concentration. The pre-concentration of the material precedes comminution processes, which involve high energy consumption. Thus, only valuable material undergoes this process and moves on to the concentration steps.

Beneficiation refers to various methods or processes that aim to increase the concentration of specific minerals through physical and chemical methods. Simply put, pre-concentration improves the overall productivity of a minerals processing plant. At Ferbasa, the use of sensor-based sorting technology has enabled an increase in production, in addition to reducing costs in the subsequent processes, such as comminution and the use of inputs, such as reagents.

Environmental, Social, and Corporate Governance (ESG) and sensor-based sorting go hand in hand

"Today, at Ferbasa, sensor-based sorting technology helps us adopt ESG practices, reducing waste, maximizing production efficiency and contributing to the conservation of natural resources", explains Eriberto Nascimento. Nowadays, it is not only the mined ore that is processed, but also the stockpiles, which contain considerable amounts of chromium. The treatment of these piles is only possible thanks to process automation and its high-capacity levels, which reach up to 180 t/h. Stockpile treatment has the potential to increase productivity in the mine. In terms of resource use, there is potential to reduce the consumption of water, energy, and chemical reagents primarily because sensor-based sorting is a dry separation process, unlike other pre-concentration processes such as dense media separation (DMS).

How all started: from curiosity to reality

Ferbasa has always used a pre-concentration process with the aim of separating lump ore, which has a high chromite content, from the low-grade ore that goes to the concentration plant. However, this used to be a manual separation process. Bartolomeu Fonseca, the former processing manager at Ferbasa, discovered an article about sensor-based sorting technology from STEINERT. In 2012, he prepared material to be sent for tests at STEINERT's Test and Development center in Germany, and these were successful.

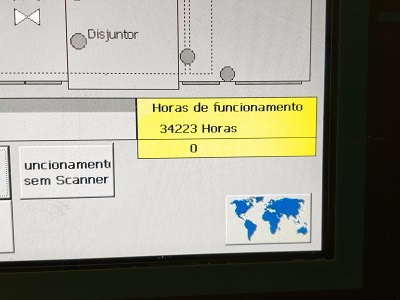

The first sorting system, STEINERT XRT, is still in operation - with 34,000 hours of runtime

Ten years ago, when the first equipment was being installed, Ferbasa's employees were sceptical about its capacity to support the adverse conditions in the mine. This is why STEINERT Latinoamericana, a subsidiary of STEINERT GmbH in Germany, offered a "try and buy agreement". Over the years, the equipment's high level of durability has been verified, resulting in the first unit still being in operation today, with a total of 34,000 hours of runtime. "Looking back, it was not easy to apply the technology, but I decided to move forward because I believed that the technology could be effective. Now, already retired, I am very proud of the legacy that I have left to the company", says Bartolomeu Fonseca. "I had the full support from the mining director at that time, Wanderley Lins, but it was my responsibility to make it work."

The first STEINERT XRT sorting system is still in operation - with 34,000 hours of runtime.

Strong support from STEINERT Latinoamericana with its own test center

In 2014, during the commissioning of the first sorting system, STEINERT XSS-T, many obstacles were faced - as is common with innovation projects. However, as STEINERT GmbH had already established its Latinoamericana subsidiary in Belo Horizonte and employed service technicians to help with installation, STEINERT Latinoamericana started a partnership with Ferbasa.

STEINERT's partnership with other companies has been paramount for the development of new solutions and technologies, contributing to the evolution of the industry and conservation of the environment. In addition, the company has been investing in research and development to continue to offer increasingly efficient and sustainable solutions.

The company currently has a team of 30 collaborators who serve several mining clients in Latin America, in addition to having a test center near the office in Brazil, enabling tests to be carried out with more convenience and efficiency for local clients.

From one to six sensor-based sorting systems in just five years

Ferbasa started operating the first equipment in 2014. By 2019, it already had six units installed for the processing of ROM and low-grade stockpiles.The production benefits from flexibility of the sorting systems, which generate waste material, pre-enriched material, and high-grade material. The processing capacities are up to 120 t/h for particles of 1 to 3 inches, reaching up to 180 t/h for particles from 2 to 5 inches. In terms of the sizes processed, the combination of sensors facilitates the separation of particles up to 5 inches; an exceptional feature that reinforces the robustness and efficiency of the equipment for the detection and ejection of extremely coarse particles. In total, recoveries reach values of up to 90%, with upgrades of up to 1,5-3 times the feed levels.

"From one to six sensor-based sorting systems in just five years proves how beneficial the operation is for the customer," says Vinícius Souto, Managing Director at STEINERT Latinoamericana.

Currently, Ferbasa applies sensor-based sorting technology to process 100% of their ROM (run-of-mine), using two units from STEINERT, the STEINERT XSS T and STEINERT KSS | XT L, in a two-step process. In the first step, waste material is rejected, and in the second, pre-enriched and high-grade materials are generated. The high grade-material meets the content specifications to be sent to the metallurgic plant, while the pre-enriched material is sent to another plant to follow other concentration procedures. Furthermore, the technology is applied in the processing of low-grade stockpiles, using two STEINERT KSS | XT L units in two steps to separate waste, pre-enriched material, and high-grade material. As a result, the low-grade stockpiles are processed in an economically viable way and with high sustainability gains.

About the technology

STEINERT has developed a unique sensor combination concept called "multi-sensor sorting" or STEINERT KSS. The STEINERT KSS sorting system applies this concept, combining the x-ray transmission sensor with three other additional sensor options (Induction, 3D laser, and Colour).

STEINERT KSS sorting system applies this concept, combining the x-ray transmission sensor with three other additional sensor options (induction, 3D laser, and colour).

Please see here also the video to this project: