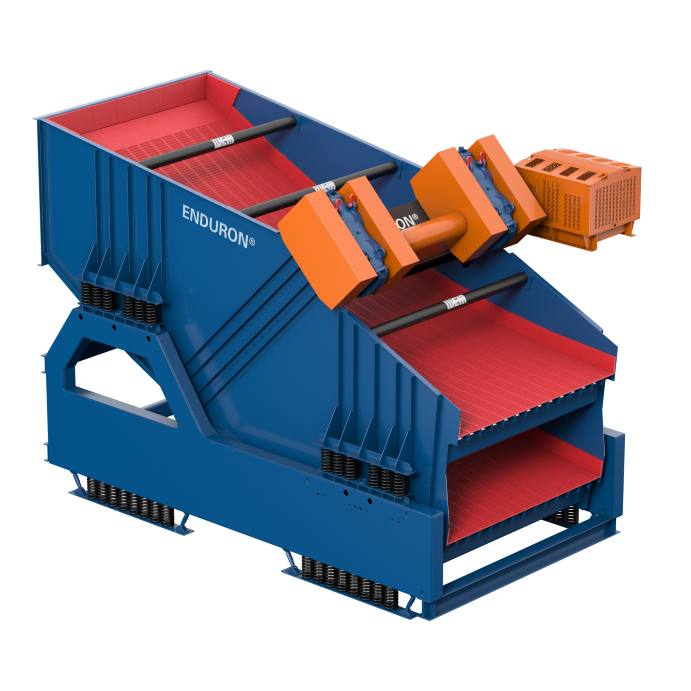

Weir's new ENDURON® ELITE screen – a large, high capacity, mining-specific machine – is one of the largest screens on the market.

It's a double-deck banana screen, available in a range of sizes with the largest weighing in at close to 50 tonnes and a deck measuring 4.3m x 8.5m.

The ENDURON® ELITE screens are driven by Weir's new ETX exciters, which drive these massive screens with just two exciters. Other machines of comparable size require three exciters.

Notably, this delivers significant advantages in terms of efficiency, lowering energy consumption, as well as simplifying the maintenance requirements.

With the exception of primary screening, ENDURON® ELITE screens can be utilised in any screening duties in the mill circuit. But they were developed and are now an integral part of Weir's transformational flowsheet solution in which traditional tumbling mills are replaced by HPGRs and vertical stirred mills, reducing energy consumption by 40%.

In short, the transformational flowsheet is a closed circuit with the ENDURON® HPGR discharge feeding the ENDURON® ELITE screen. The oversize material from both top and bottom decks is recycled back to the HPGR, while the bottom deck undersize product is fed to the vertical stirred mill.

These big banana screens are able to separate material efficiently at small cut sizes, ensuring that Weir can offer a single mill flowsheet, allowing miners to significantly reduce their energy consumption and operating costs, compared to traditional tumbling mills.

Intelligent solutions

ELITE screens can also be digitally enabled, providing the operator with greater visibility of equipment health and performance, as well as providing the opportunity for process optimisation.

Weir's intelligent solutions monitor bearing health, temperature, vibrations, acceleration, throw angle and overall screen health.

Condition monitoring solutions provide a holistic view of the equipment from a health and performance perspectives. Weir's intelligent solutions integrate multiple data sources from IIoT sensors on the equipment and the process around it, as well as back-end data sources, such as its ERP (enterprise resource planning), engineering systems and product master data systems.

This allows Weir to build intelligent formulas that provide actionable insights, recommendations and event intelligence beyond what any typical condition monitoring system can do.

For instance, as an OEM, Weir is able to integrate the design, manufacturing, operating and maintenance data of its ENDURON® ELITE screens, combined with the live IIoT sensor data, to deliver an algorithm able to generate predictive recommendations on equipment operation.

These recommendations are then automatically ‘pushed' to the customer or, if in place, Weir service staff, alerting them to a potential problem ahead of time, as well as recommended actions to take.

These individual pieces of intelligent equipment can then be made to talk to each other, which then allows for the optimisation of entire flowsheets.

If you'd like to learn more about Weir's ENDURON® ELITE screens or its intelligent solutions, visit booth #8833 in the Central Hall at this year's MINExpo.

ABOUT THIS COMPANY

Weir

With world class engineering expertise, Weir works in partnership with our mining customers to solve their operating challenges safely, efficiently and sustainably.

CONTACT DETAILS:

- Website: http://www.global.weir/

- Email: https://www.global.weir/contact-us/