As part of its mission to pioneer industrial machinery solutions for the mining industry, Metso has introduced a new range of analyzers, designed to meet the market's growing demand for utilizing advanced digital solutions over traditional processes.

Metso's Director of Analyzer Solutions, Juha Timperi, is especially excited about the recent portfolio. Amongst a variety of reasons, this is because the whole value chain of battery metal production now falls within Metso's orbit. It encompasses everything from cobalt, nickel and spodumene concentration, to the refining of battery chemicals, and then all the way through to end-of-life battery black mass recycling.

Metso has not only embraced utilization of the latest and best available technologies, but has in fact helped to lead and steer the significant changes currently transforming the mining industry today due to digitalization.

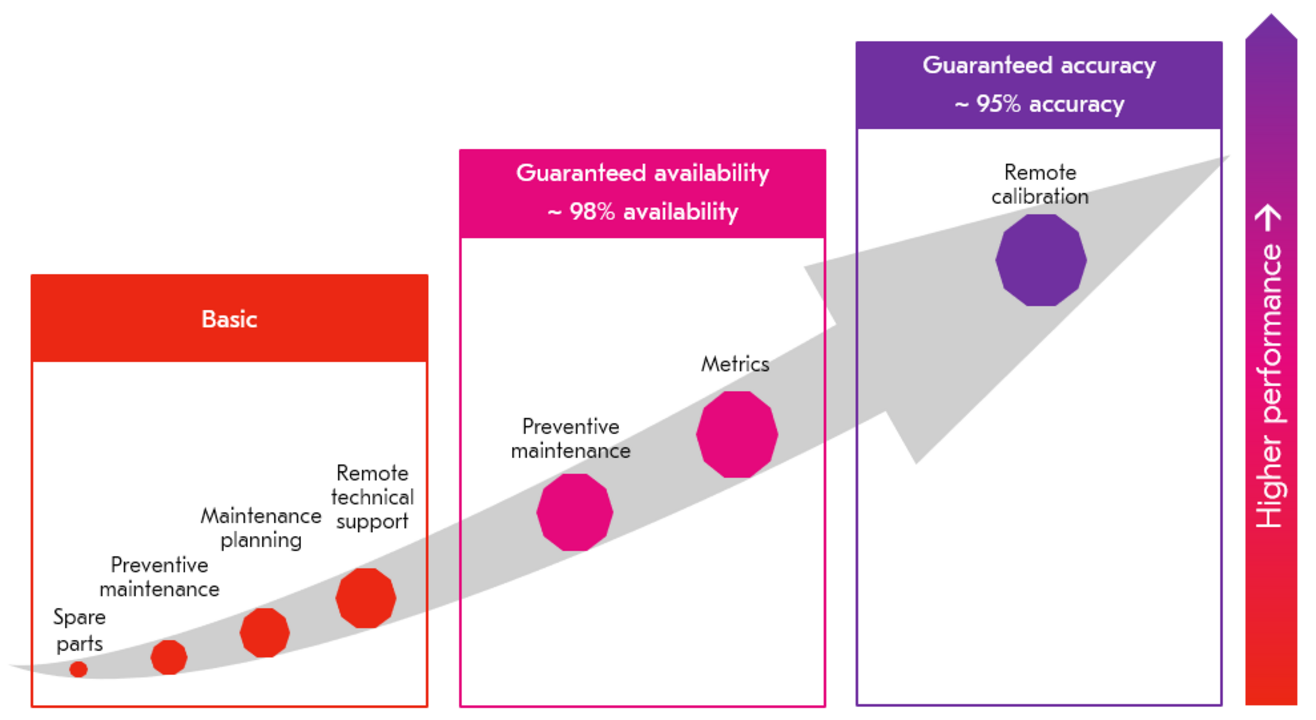

For example, Timperi pointed to Metso's new digital services, which exemplifies the company's position as an innovation leader in the mining automation space. The increased analyzer availability and accuracy provided by Metso's new digital service products, such as Metso Metrics, have the potential to deliver substantial material benefits throughout the life cycle of a plant.

Introducing a new member to the family of PSI® particle size analyzers

Regarding specific products, Metso's PSI® range of particle size analyzers offer the lower total cost of ownership. This is due to the extended life cycle, improved availability, minimized operating costs and optimized process results it comes with.

The newest addition to Metso's PSI® family is the PSI® 1000, which has been designed to perform precise monitoring and enhance efficiency in hydrometallurgical and chemical production, with a focus on battery precursor materials (pCAM). This system offers real time analysis, allowing for immediate adjustments to reach and maintain optimal production conditions. It has the ability to operate continuously and requires little maintenance, thus guaranteeing an uninterrupted flow of real-time data and analysis results.

Meanwhile, the PSI® 300i and PSI® 500i particle size analyzers can be used to monitor and optimize the operation of grinding circuits, flotation units and thickeners in minerals processing applications.

Condition Monitoring via Metso Metrics

Metso Metrics is a digital platform that enables remote condition monitoring service from the company's various Performance Centers. These Metso technology and knowledge hubs provide remote digital services to help make mining operations more efficient, profitable and sustainable.

The process is customer-led, whereby the advanced data analytics tools used to support meeting targets are always discussed together first, to set the basis for continuous improvement. Real-time data is then sent to the Metrics cloud platform, and in most cases, already existing data is used without the need to retrofit sensors.

Metrics Monitoring for Analyzers was developed by combining technology innovation with accurate analytics. The remote platform connects equipment and displays operating data in real-time, while continuously tracking the machine's health, resulting in proactive operational optimization and maintenance.

This enhanced connectivity means the analyzer can inform service personnel if components require urgent maintenance, thus enabling preventive maintenance before failure. By implementing proactive or planned maintenance – as opposed to reactive, corrective maintenance – customers are lowering their overall costs and increasing asset availability.

In addition, optimized measurement performance for the analyzer is archived via Metso's remote calibration services, keeping analyzer measurement errors as low as possible.

Metrics Monitoring for Analyzers also reduces the need for on-site presence of Metso's experts by enabling remote operation and troubleshooting. This reliable support increases sustainability and further helps companies achieve their environmental targets.

Available for both Metso's Courier® and PSI® range of analyzers, Metrics Monitoring for Analyzers incorporates a feature that provides a system overview of equipment. The overview encompasses timelines and measurements, as well as active alarms and warnings. Furthermore, specific equipment sections can be selected for deeper analysis.

Secured equipment reliability and accuracy level

Metso's customizable Life Cycle Service (LCS) packages help mitigate the risks for companies wrestling with a looming skills shortage by providing equipment support, maintenance and optimization. By automating monitoring and allowing for remote troubleshooting, Metso's customers can redirect their focus and resources on identifying and addressing the root causes of their analyzer issues.

Life Cycle Services Product Manager, Manu Veuro, emphasized the importance of digital tools in monitoring equipment health, performance and service needs. He also confirmed that Metso's remote calibration service guarantees high analyzer measurement accuracy, allowing metallurgical specialists to concentrate more on process improvements.

Veuro also pointed out that as a contract model, LCS is flexible and customizable, as its scope can be altered based on evolving conditions and dynamics at the site. He explained that Metso's belief in the merits of a one-stop-shop solution mean equipment is regulated and governed via one contract, with all communication going through a single point of contact.

This creates an optimal setting for enhanced efficiency, as the actions necessary to keep equipment in premium condition can be quickly identified and carried out. This inevitably maximizes uptime for the operations, as well.

Customer-led revolution

Metso provides unrivalled knowledge and a range of technologies to control and optimize minerals processing and hydrometallurgical plants. Even early in the plant's design phase, they work with customers to select the best solution for the job.

Metso understands that operations are looking for real-time process control in demanding plant conditions, guaranteed on-demand availability of spare parts and on-site support for minimum possible downtime. To address this, Metso's global service network is available to support in troubleshooting on fast response time via remote connectivity. If required, their certified field service technicians are also available to travel on-site with necessary spare parts.

As a part of a Life Cycle Service (LCS) package, Metso experts will advise on the need of critical on-site spare parts to reduce the lead-time related to spare part delivery.

Metso also recognizes the primary purpose for analyzers and other measurement instruments is process control. Their process metallurgists and control engineers are available to support customers with Advanced Process Control (APC) solutions.

These important differentiators available in the new range of analyzers elevate the current portfolio, offering unmatched sensitivity, reliability and shorter cycle times. This results in more efficient process management, monitoring and control across various mineral processing plants.

Metso understands the customer's world and the daily challenges they face. That's why, together, they are the partners for positive change.

ABOUT THIS COMPANY

Metso

Metso is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. We improve our customers’ energy and water efficiency, increase their productivity, and reduce environmental risks with our product and service expertise.

HEAD OFFICE:

- Rauhalanpuisto 9, 02230, Espoo, Finland

- Phone: +358 20 484 100

- Web: www.metso.com/