Advanced Mill Liner Solutions

Grinding mill liners are essential for achieving optimal mill performance. At ME Elecmetal, we prioritize innovation in liner and alloy design to enhance efficiency, reduce relining costs, and minimize downtime. Through close collaboration with our customers, we conduct in-depth application analyses to determine the best design and material combination. This approach ensures superior wear performance and maximized throughput for AG, SAG, ball, rod, and tower mills. By continuously monitoring wear performance and production rates, we fine-tune mill operations for peak efficiency. Our technical solutions provide substantial operational benefits while maintaining the lowest total cost of ownership.

Designed to withstand both high-impact and high-abrasion conditions, our liners meet the most demanding operational challenges. Additionally, our advanced condition monitoring services provide real-time insights, further enhancing mill performance.

Cutting-Edge Liner Technologies

ME PolyFIT® Hybrid and Composite Liners

ME PolyFIT is ME Elecmetal's innovative line of hybrid and composite products, engineered with wear-resistant rubber compounds to meet the specific needs of the mining industry. Designed to replace high-wear components, these liners integrate seamlessly with ME Elecmetal's steel liners, providing an optimal balance of durability, weight reduction, and operational efficiency.

Key benefits of ME PolyFIT® liners include:

- Extended lifespan and minimized downtime

- Reduced mill volume occupancy

- Fewer components for faster installation

By adopting these hybrid solutions, customers can significantly enhance equipment efficiency and optimize operational performance

ME SecureFIT® Bolting and Fastening Solutions

ME SecureFIT® External Bolting

There is a growing need for safer alternatives that can improve operational safety while maintaining or enhancing efficiency in maintenance routines. ME SecureFIT® external bolting is a revolutionary fastening solution designed to improve safety and efficiency in SAG mill maintenance. This innovative system uses externally inserted bolts, eliminating the need for personnel to enter the mill for bolt installation. By reducing human-machine interaction, ME SecureFIT® significantly enhances worker safety while maintaining mill efficiency.

ME SecureFIT® Smart Bolting System

As part of the ME FIT Program, ME SecureFIT Smart Bolting System (SBS) revolutionizes fastening in mining operations by enhancing safety, reliability, and productivity. This advanced solution ensures proper bolt operation while enabling predictive maintenance for mill liners and other critical equipment.

Why Choose ME SecureFIT® SBS?

ME SecureFIT® SBS is the only solution on the market that integrates cutting-edge technology with high-quality fastening systems, supported by tailored training and expert advisory services to meet each customer's unique needs.

Online Bolt Tension Monitoring

ME SecureFIT SBS uses sensorized bolts to provide real-time tension monitoring, preventing loosening and fractures in mill bolts and other mechanical systems. This ensures optimal fastening performance and extends equipment life.

Key Benefits:

- Installation Expertise – Professional guidance on bolt tension measurement for ball mills, SAG mills, and other industrial equipment.

- Predictive Maintenance – Real-time tension data enables proactive re-torquing and maintenance, reducing downtime and increasing operational efficiency.

- Versatile Applications – Suitable for:

- Ball mill and SAG mill bolt tension monitoring

- Thickener bolt tension measurement

- Other critical industrial applications where bolt integrity is essential

With ME SecureFIT® SBS, mining and industrial operations gain unparalleled control, reduced maintenance risks, and improved performance, setting a new standard for mill fastening solutions.

Expertise-Driven Optimization

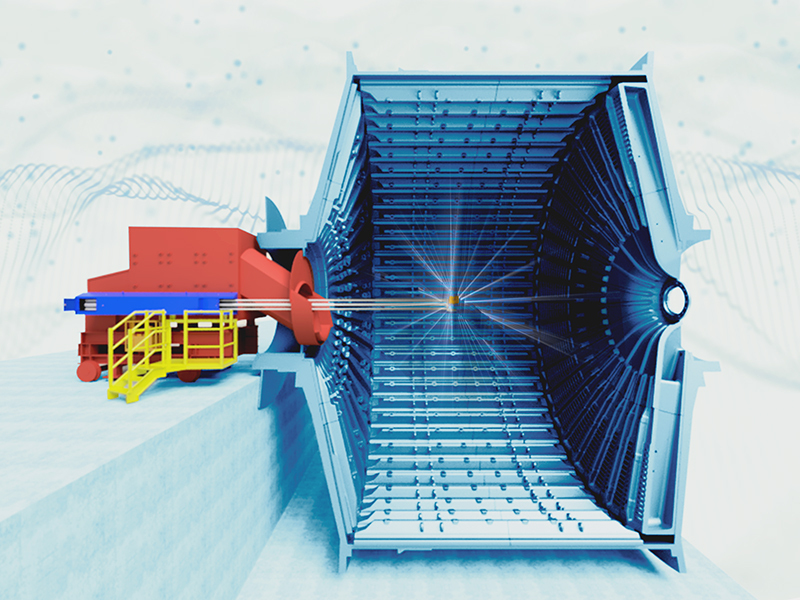

Optimization Tools and Services

ME Elecmetal leads the way in industry innovation by harnessing advanced digital tools to optimize grinding operations. Our comprehensive suite of optimization tools delivers critical insights and wear monitoring capabilities, ensuring every decision is data-driven and aimed at maximizing performance. However, our commitment goes beyond just delivering innovative tools—we work closely with our clients to provide expert guidance, continuous support, and tailored solutions that drive long-term success.

Additionally, we deliver unmatched technical support and training, empowering clients and their teams with the skills and knowledge needed for peak performance. Our services include precise 3D laser scanning™ and QuickScan™ Grinding, a scanning system for SAG mills that eliminates the need for personnel entry into the mill utilizes and allows full scans to be completed in just 15 minutes! We also offer optimized liner change-out processes to minimize downtime, and continuous improvement programs that uphold long-term operational excellence.

With ME Elecmetal, you gain a trusted partner dedicated to maximizing equipment performance, reducing operational risks, and delivering sustainable success

Sustainability and Supply Chain Excellence

Circular Economy Initiatives

ME Elecmetal is committed to sustainable manufacturing, offering 100% recyclable cast liners and a hybrid recycling process for large and medium-sized components. Through strategic partnerships, we have developed technologies to recover scrap grinding balls and remanufacture critical equipment components, reinforcing our commitment to sustainability.

Global Supply Chain Strength

With ten state-of-the-art metallurgical plants in Chile, the USA, Peru, China, South Africa, Indonesia, and Zambia, ME Elecmetal ensures efficient localized supply, faster product deliveries, and tailored solutions that meet customer demands worldwide.

Fully Integrated Technology: ME FIT® Programs

ME Elecmetal's ME FIT® Programs are designed to foster continuous improvement and drive medium- to long-term research and development in close collaboration with our clients and a multidisciplinary team at ME Elecmetal. These initiatives focus on strategically aligning with our clients' goals, and delivering tangible results through a systematic, integrated, and structured approach. This ensures sustained performance improvements and enhanced operational efficiency, helping clients achieve long-term success and optimized outcomes in their operations.

ME FIT Grinding

ME FIT Grinding provides customized solutions according to unique requirements, customer production strategies, and productivity goals. We integrate analysis of available operational data with data generated through in-house simulations and more than 100 years of experience in parts design and manufacturing. We validate our performance through controls and measures to monitor our solution's impact on our client's key performance indicators: productivity, reliability, availability, safety, efficiency, and energy consumption. Our ME FIT processes ensure that we constantly add value to our customers' mill operations through liner design, quality, and material improvements.

VAP Philosophy

Our VAP framework is a strategic methodology designed to overcome complex operational challenges. By delivering holistic solutions that optimize mining operations, we foster long-term, trust-based partnerships. Through ongoing product innovation and service excellence, we remain dedicated to enhancing operational efficiency and sustainability.

At ME Elecmetal, we understand that success in the mining industry requires advanced technology and unwavering client support. We provide the tools, knowledge, and ongoing assistance necessary to elevate your mining operations.

Connect with Us Today!

Discover more about our ME FIT Programs and a range of tailored solutions by visiting www.me-elecmetal.com or calling us at 480-730-7500.

Mark Your Calendars!

Join us from May 4–7, 2025, in St. Montreal, Quebec for CIM Connect 2025! Stop by Booth 2222 to meet the ME Elecmetal team and explore the latest innovations and solutions transforming the mining industry. Visit our website for more info: https://usa.me-elecmetal.com/en-us/events/cim-connect-2025.

We look forward to connecting with you!

About ME Elecmetal

ME Elecmetal is a leading global supplier and strategic partner in the mineral processing, aggregate, construction, and recycling industries, renowned for its commitment to innovation and technology. Dedicated to delivering cutting-edge, sustainable solutions, ME Elecmetal consistently exceeds customer expectations worldwide.

With a comprehensive range of products and services—including grinding media, mill liners, crusher liners, and large specialty castings—ME Elecmetal is the preferred partner for crusher operators and mineral processors looking to optimize their operations.

The company operates ten state-of-the-art metallurgical plants strategically located across Chile, the USA, Peru, China, South Africa, Indonedia, and Zambia. With a robust manufacturing capacity exceeding 134,000 tons for foundry products and 600,000 tons for grinding media, the company continues to meet the growing demands of the mining industry.

ME Elecmetal's commercial presence extends to over 40 countries, solidifying ME Elecmetal's position as a global leader in delivering innovative solutions to the mineral processing, aggregate, construction, and recycling sectors.

Learn more about ME Elecmetal's global footprint and commitment to excellence in integral solutions at www.me-elecmetal.com.

ABOUT THIS COMPANY

ME Elecmetal

ME Elecmetal is a global supplier with more than 100 years of experience as a supplier and strategic partner for total wear product solutions in the mineral processing, aggregate, construction and recycle industries. We are the preferred supplier for mineral processors seeking improvements in their grinding mill processes. Our range of products include: grinding media, mill liners, crusher liners, large specialty castings, slag pots and ground engaging tools. Our range of services include: service centers, engineering and design, Early Alert and ME FIT System®. ME Elecmetal has 1,200+ employees and serves customers in 35+ countries around the world.

United States Offices

- 4500 S Lakeshore Drive, Tempe, AZ 85282, 480-730-7500, United States

- 3901 University Ave NE, Minneapolis, MN 55421, 763-788-1651, United States

- Tel: 4807307500

- Email: marketing@meglobal.com

- Website: www.me-elecmetal.com