While well-established, traditional methods for measuring geometric changes also have well-known limitations. Recent disasters in the mining industry have underlined the need for high-quality, detailed data and early warning systems, especially in areas like surface mines and tailings storage facilities.

3D laser scanners offer a compelling solution. Unlike manual monitoring methods, they can be permanently installed and provide real-time data without the need for upfront knowledge of specific processes.

In addition, these scanners can be integrated into comprehensive risk management systems. and complement existing sensor technology.

Mining Magazine interviewed Thomas Gaisecker, a specialist in mining applications at RIEGL, about the transformative potential of 3D scanner technology for the mining industry.

The discussion delves into the key distinctions between radar and LiDAR technologies, highlighting LiDAR's superior ability to capture intricate surface details crucial for slope monitoring and overall safety.

Gaisecker emphasises the advantages of 3D scanners in real-time data capture, eliminating the need for manual processes and reducing human exposure to hazardous environments. He explains how the scanner tackles large data volumes through onboard processing and efficient storage solutions.

Q: Can you explain the key differences between radar and LiDAR technologies for mining monitoring applications?

A: Both radar and LiDAR technologies play essential roles in mining monitoring, each offering unique strengths. Radar excels in high-accuracy measurement down to millimetres and can penetrate through adverse weather conditions like clouds, rain, and dust. However, its drawback lies in its larger footprint, which limits detailed surface analysis. On the other hand, LiDAR consists of a much sharper laser beam that provides intricate surface details, making it ideal for applications like slope monitoring, landslides, and general mining safety. Additionally, LiDAR setups are more flexible and easier to install compared to radar installations.

Q: How does the integration of LiDAR and other sensors enhance mining safety and efficiency?

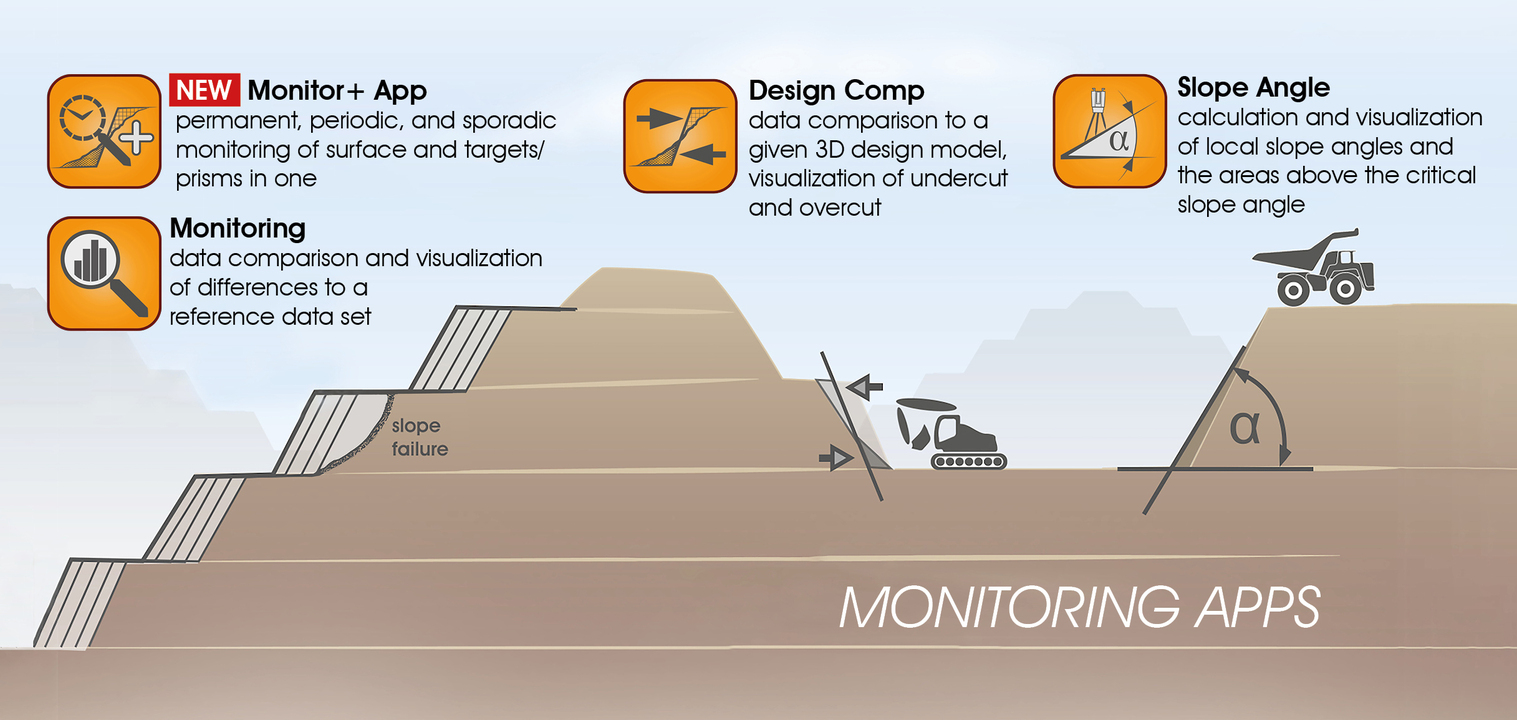

A: Integrating LiDAR with other sensors creates a comprehensive monitoring solution tailored to mining needs. For instance, in slope monitoring, combining LiDAR with apps like the slope angle app can deliver real-time data on slope stability, crucial for preventing accidents. LiDAR's ability to capture detailed surface changes complements other sensors, providing a holistic view of mining environments and enabling proactive safety measures.

Q: What are the advantages of using a 3D scanner for real-time data capture in mining operations?

A: A 3D scanner offers unparalleled convenience and efficiency in mining operations. By automating data capture and processing, it eliminates the need for manual post-processing, ensuring continuous 24/7 monitoring with minimal human intervention. This streamlined approach significantly enhances safety by reducing the need for personnel to enter hazardous areas for data collection, a critical factor in mining environments where safety is paramount.

Q: How does the 3D scanner handle large data volumes in mining monitoring?

A: Mining monitoring generates substantial data volumes due to frequent scans, sometimes as large as 500 megabytes per scan. To manage this efficiently, the 3D scanner performs onboard data processing, condensing raw data into processed images stored as compact files. This optimisation allows for seamless data synchronisation to network or cloud storage, minimising bandwidth requirements while preserving critical monitoring information.

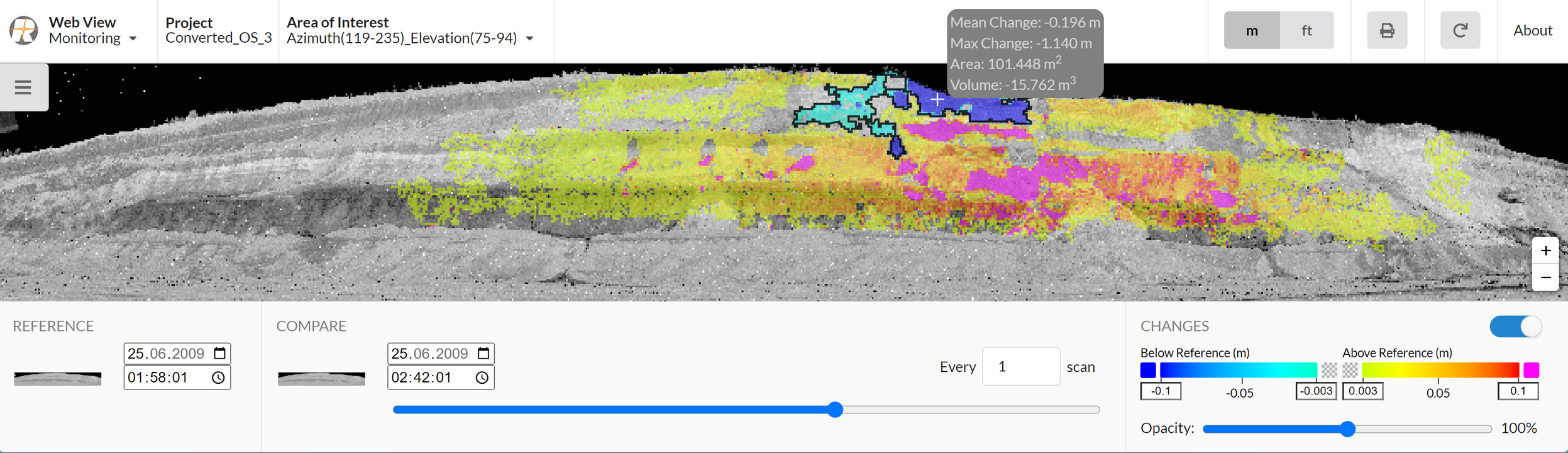

Q: Can you explain the significance of using images derived from LiDAR data for change detection in mining applications?

A: Images derived from LiDAR data offer intuitive visualisations of surface changes over time, crucial for identifying potential risks like erosion and landslides. By overlaying and comparing images from different dates, mining personnel can easily pinpoint areas of concern and track changes without specialised software. This accessibility enhances safety and facilitates proactive decision-making in mining operations.

Q: How does the 3D scanner's technology differ from traditional prism monitoring methods in mining?

A: Unlike traditional prism monitoring methods, which rely on physical markers that require maintenance and pose safety risks, the 3D scanner offers a non-intrusive, automated solution. By capturing detailed surface data and detecting subtle changes, the scanner provides comprehensive monitoring without the need for manual interventions or specialised software, revolutionising safety practices in mining environments.

Q: What future applications do you envision for 3D scanner technology beyond safety in mining?

A: The versatility of 3D scanner technology extends beyond safety applications to improve overall mining productivity. For example, the slope angle app leverages the same data to ensure optimal dump area conditions, showcasing its potential for enhancing operational efficiency. Moreover, its adaptability makes it suitable for diverse environments like urban planning, where real-time data visualisation can inform infrastructure development and risk assessment.

Q: How do you approach training and deploying this system in a new mine? What is involved in training new staff to use it effectively?

A: Deploying the system in a new mine involves straightforward training and setup processes. While configuring the system initially can be complex due to its flexibility and numerous options, the actual usage on-site is designed to be user-friendly. The training typically includes steps such as scan position and scan pattern settings, area of interest definition, and scheduling configurations using our software's app configuration wizard. Once configured, the settings are exported to the scanner, where setup is as simple as mounting the scanner, loading the configuration, and starting the monitoring app. This intuitive design minimizes the learning curve for new staff, ensuring swift deployment and effective utilization of the monitoring system.

Q: How have miners reacted to this new system? Have you received feedback from customers who have implemented it?

A: The system has received positive feedback from miners who have implemented it in their operations. Existing customers who initially purchased the scanner for standard surveying tasks have been impressed by its added functionality in monitoring applications. They appreciate the system's versatility, allowing them to seamlessly transition between monitoring and surveying tasks without compromising on accuracy or efficiency. This positive reception underscores the system's potential to revolutionize traditional monitoring approaches in mining environments.

Q: Can you explain the significance of design comparison using this system in open pit mining? How does it benefit mine planning and safety?

A: Design comparison is a crucial feature derived from customer feedback and tailored to meet the specific needs of open pit mining operations. By comparing real-time data to a designated design model, miners can visualize overcuts and undercuts, highlighting deviations from the planned mine design. This information is vital for optimizing mine design to ensure operational safety and cost efficiency. Miners can identify areas where material extraction is feasible (undercut) versus areas posing safety risks (overcut), enabling informed decision-making in mine planning and management.

Q: How does the system support periodic and sporadic monitoring in mining operations?

A: The system's flexibility supports different monitoring modes, including periodic and sporadic monitoring. Periodic monitoring involves continuous data collection over specific periods, ideal for ongoing surveillance of critical areas. In contrast, sporadic monitoring allows for intermittent scanning, accommodating scenarios where the scanner needs to be relocated temporarily. This versatility ensures that the system can adapt to varying operational needs, providing miners with tailored monitoring solutions based on the specific requirements of their mine sites.

Q: Could you elaborate on the system's application in avalanche detection and extreme environments?

A: The system's capabilities extend beyond traditional mining applications to include avalanche detection and monitoring in extreme environments. Scanners like our RIEGL VZ-6000 are optimized for long-range scanning even in snowy conditions, making them suitable for avalanche detection. By leveraging advanced scanning technology, the system can contribute to avalanche risk assessment and mitigation efforts, enhancing safety in mountainous regions susceptible to avalanches. This underscores the system's versatility and potential for diverse applications beyond conventional mining monitoring tasks.

Q: Does this monitoring application have applications underground as well?

A: While the primary focus has been on open-pit mining, the monitoring application can indeed be utilized underground without any issues. The system's functionality remains consistent whether deployed in open-pit, underground, or other mining environments such as tunneling or quarrying.

Q: How real-time is the monitoring frequency compared to other solutions like satellite imaging?

A: Our monitoring system offers a near-real-time capability, with data updates available shortly after each scan. For instance, a high-resolution, long-range scan of over 1000 meters takes approximately 15 minutes to complete, with processed data accessible within five minutes. The frequency of monitoring can be adjusted based on resolution requirements, with intervals as short as every hour providing substantial data for analysis. This frequency surpasses traditional satellite monitoring, which may only provide updates once per week in some cases.

Q: Can you elaborate on the significance of human interpretation in analyzing monitoring data?

A: The system's data requires human interpretation, particularly by geological or geomorphological specialists who possess contextual knowledge of the monitored area. Automated alarming systems are not employed due to the nuanced understanding needed to differentiate between natural processes and potential anomalies. Specialists can discern critical changes from normal fluctuations, ensuring that alarms are triggered only when truly warranted. This approach minimizes false alarms and avoids unnecessary disruptions in mining operations, where downtime can incur significant costs.

Q: How does the system's visual interface facilitate human interpretation of monitoring data?

A: The system's interface presents monitoring data in an image-like format that is easily interpretable by geological specialists without requiring advanced computer expertise. This visual clarity enables specialists to make informed decisions based on real-time observations, contributing to accurate risk assessments and proactive management of geological hazards. The goal is to empower specialists with accessible, actionable data that enhances safety and operational efficiency within mining environments.

Q: What are the advantages of using LIDAR technology for monitoring geomorphologic changes?

A: LIDAR technology offers unparalleled precision in detecting subtle geomorphologic changes, even over expansive areas. By generating detailed point clouds, LIDAR enables the identification of minute surface variations that may indicate potential hazards such as landslides or erosion. The system's ability to capture high-resolution, three-dimensional data facilitates comprehensive analysis by specialists, ensuring that mining operations are conducted with heightened awareness of geomorphologic dynamics.

Q: How does the system address the need for continuous monitoring without automatic alarming?

A: Continuous monitoring without automatic alarming emphasizes the importance of human oversight in interpreting monitoring data accurately. By integrating LIDAR technology with a user-friendly interface, the system equips specialists with the tools needed to assess dynamic land surface conditions effectively. This approach prioritizes informed decision-making over automated responses, aligning with the operational requirements of mining environments where human expertise remains indispensable.

Q: What are the potential future developments in automated alarming for mining applications?

A: While advancements in artificial intelligence and deep learning hold promise for automated alarming, the current emphasis is on refining the system's interpretability for human specialists. Future iterations may incorporate AI-driven algorithms to enhance anomaly detection and reduce reliance on manual oversight. However, the priority remains on maintaining operational reliability and minimizing disruptions, especially in high-stakes mining operations where downtime carries substantial financial implications.