Today we are looking at some of the providers of equipment and solutions for surface mines.

For more information on the exhibitors, such as booth numbers, see the official Bauma website.

Bell Equipment

Bell Equipment will use Bauma to display both new and proven models of its E-series truck range. Focal points will include the conversion to new emission regulations, model-specific improvements and the group's worldwide commitment to pro-active customer support strategies.

In addition to the world premiere of its latest ‘crossover' model, the Bell B45E 4x4, the company's 6x6 range comprising seven models with payloads from 18t-45.4t will be represented by the Bell B20E LGP (Low Ground Pressure) - a new addition to many market regions - and the Bell B50E.

At Bauma, Bell Equipment will update the market on the transition of its truck technology from emission level EU Stage IV/Tier 4F to meet the new EU Stage V regulations that became effective at the beginning of 2019. This impacts engines from long-time Bell partners Mercedes-Benz/MTU.

These engines complied with EU Stage IV in combining integrated cooled exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) adding urea (AdBlue). The new after-treatment process now adds a diesel oxidation catalyst (DOC) and a diesel particulate filter (DPF).

The other big change is on the high-volume Bell B30E model, which includes the introduction of the new Allison 3400 XFE transmission (6F / 1R).

At the show, customers from around the world will be informed about the latest developments in Bell Equipment's after-market services. This includes new features of the satellite-based fleet management system Fleetm@tic, financing programmes, and new repair and maintenance offerings that can be tailor-made for each type of application and customer profile.

Bell Equipment states that the introduction of 60t tonne ADTs increased customer interest in the B50E

Boart Longyear

Boart Longyear has introduced various geological data services and instrumentation over the last few years to complement its drilling services and products divisions.

The company's instrumentation line-up includes TruShot digital downhole survey technology, which was introduced in mid-2018 and is used to capture high-quality, three-dimensional hole path data and to precisely determine the azimuth and dip measurement of boreholes. Oriented core is increasingly playing an important role in deposit definition and structural analysis. The TruCore core-orientation tool provides a solution to determining the true direction of the mineralisation of a geological feature, deposit and the associated structure.

Boart Longyear's TruScan on-site core and chip scanning technology provides geologists with non-destructive, accurate, high-density elemental concentration data for same-day continuous analysis of drill core.

Boart Longyear representatives will be discussing several new drilling products and services during Bauma that it says are proving to increase safety, reduce wear, lessen environmental impact and improve cost-effectiveness. Capabilities and equipment to be highlighted will include the LS250 MiniSonic rig, which was developed for a wide variety of soft ground and shallow drilling projects.

Also at the Boart Longyear stand, the company's line of Longyear diamond coring bits will be on display. Engineered to drill faster and last longer, Longyear bits can improve shift performance and ultimately put more core in the box. Additionally, the new XQ wireline coring rod will be featured that has a self-aligning thread start geometry to ensures mating threads engage smoothly, without wedging or jamming

In January, Boart Longyear announced its newest top-hammer tooling line, the DriftMaster series of rods and bits. DriftMaster rods and bits are designed with a unique thread profile for added endurance and strength in the most demanding tunnelling, bolting and drifting applications.

Boart Longyear's TruCore core-orientation tool

Bridgestone

Tyre and rubber company Bridgestone is returning to Bauma to present a selection from its range of tyres, industrial products and targeted solutions.

Bridgestone produces tyres for everything from bicycles to aircraft, including the world's largest mining trucks. One of these four-metre-tall tyres, the largest in the world according to the company, will be on display at the Bridgestone stand.

It will be joined by a number of other tyres, including brand-new products: VSDL Loader tyre 33/65R29 - the first wheeled-loader tyre to combine the benefits of the super-wide-base 65 series with the deep Bridgestone VSDL tread pattern; and VLTS articulated dump truck (ADT) tyre - recently launched, this tyre was specifically developed for the 60t ADT from Volvo Construction Equipment.

Bridgestone has also developed digital solutions to maximise the potential of these products, making the most of the digital technology that is being increasingly integrated into vehicles and machinery to increase productivity, decrease downtime, maximise operational potential and minimise the risks to personal safety.

Part of the Total Tyre Care approach, two specific solutions will be presented at Bauma: Tirematics TPMS - the first tyre pressure monitoring system to focus primarily on fleet pressure measurements for individual machines; and FleetPulse - a mobile and web application designed to help fleet customers maximise the health and performance of vehicles, while improving uptime and reducing total cost of ownership and digitising operations.

The Bridgestone stand at Bauma

Caterpillar

Caterpillar will be showcasing several of its mining and off-highway trucks at Bauma. For example, the new 777G off-highway truck will be on display; it has a 100 short ton (90t) payload and features a Cat C32 engine rated at 945 net horsepower (704kW) with US Tier 2 equivalent emissions. The new truck features a refined cab that positions the operator seat on the left side, along with a new console with an integrated hoist and shift lever.

The new 777G provides customers a choice of bodies. The 60.1m3 dual-slope body is designed for maximum material retention on grades and has two side-board configurations available for light material, as well as a rubber liner. The X-body is designed with a flat floor to better meter material into a crusher and is available with either steel or rubber liners.

Cat articulated trucks will also be represented at Bauma by the completely redesigned 730, which weighs 22% less than its predecessor, the 730C, while retaining 98% of its predecessor's capacity. The new truck features automatic control of traction, dumping, and retarding, as well as the Caterpillar Stability Assist system.

Caterpillar technology that keeps operators safe, comfortable and productive also will be on display at Bauma with the D8T dozer remote-control station. With multiple levels of remote control and even semi-autonomous operation, Cat Command for dozing is available in two configurations - an over-the-shoulder remote-control console or the remote-operator station. Operators have full control of the dozer without being exposed to job-site hazards.

The company's underground mining equipment will be represented by the Cat R1700 loader. It handled payloads of 15t, which is 20% more than its predecessor. High breakout forces and a traction-control system can also increase production potential.

The cab of the new Cat 777G off-highway truck

Doosan

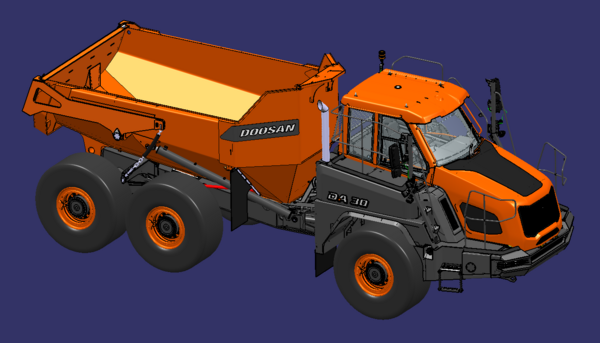

Doosan Construction Equipment will be showing a wide range of new products for the first time at the Bauma 2019 exhibition, including the new 30t and 40t class Stage V compliant articulated dump trucks (ADTs).

The developments in the new Stage V ADTs have resulted from intensive market analysis, customer visits, interviews with operators and additional feedback gathered by the product/R&D teams at Doosan's ADT plant in Molde in Norway.

In 2018, the DA30 ADT was upgraded with a range of features including a new cab, a new self-levelling front suspension and a new tandem bogie system which are all incorporated in the new Stage V model. A similar process has been applied in the new 40t Stage V machine, with a new cab and a semi-levelling front suspension that adjusts itself independently depending on the operating conditions to ensure a comfortable working environment for the operator.

As well as these changes, the new Stage V models offer many more features, such as a new design for the front frame and bonnet components on the trucks, created by the Doosan Design Team in accordance with the latest trends in the market.

Complementing the striking external changes on the new ADTs, are the new Scania Stage V compliant 9L and 13L engines that now power the machines. The new Scania engines have undergone two years of very intensive testing in exacting construction and mining environments over the last two years. Whilst the core of the Scania engines has not changed, the main difference in the new engines from their predecessors is the improved after-treatment system.

In 2018, the Doosan DA30 ADT was upgraded with a range of features

Goodyear

Goodyear will be featuring its flagship products and solutions for fleets operating in the worlds of construction and mining at Bauma.

In addition to the recently-announced Goodyear OMNITRAC mixed service tyre range, which makes its exhibition debut at the show, the manufacturer will also showcase its Goodyear Proactive Solutions TPMS Heavy Duty, EMTrack tyre management system and the TL-4A off-the-road tyre.

"Goodyear offers a comprehensive portfolio of tyres and tyre-related solutions for all vehicle types operating in construction," says Octavian Velcan, managing director, off-the-road tyres at Goodyear EMEA. "The increasing use of data connectivity on vehicles provides various opportunities for integrating tyre management solutions that minimise tyre-related issues as well as reduce downtime and costs. Our constantly evolving Goodyear Proactive Solutions TPMS Heavy Duty and EMTrack tyre management system use the latest technology to provide not only real time feedback, but also to ensure that vehicles operate to their optimum, reducing the total cost of ownership wherever and whenever those vehicles are operating."

Goodyear will be featuring its flagship products and solutions for fleets operating in the worlds of construction and mining at Bauma

Liebherr

Once again Liebherr has big plans for its outdoor exhibition area. Amongst many other products, the company will unveil INTUSI, its INTeractive USer Interface which it says will "revolutionise the communication between and with construction machines".

INTUSI connects Liebherr construction machinery and material handlers to the Internet of things (IoT) and combines intelligent operating logic with machine intelligence.

The objective during development was to provide machine operators with a future-focused machine interface with Liebherr's characteristic transparency and clear overall logic. Going forward, INTUSI will used in all Liebherr earthmoving machines and material handlers.

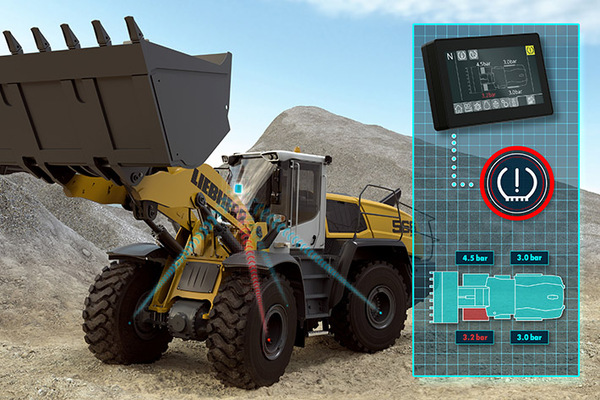

Liebherr will also present a range of intelligent assistance systems for its XPower large wheel loaders. These include a new active rear person recognition and a sensor-supported, integrated tyre pressure monitoring system, as well as an intuitive steering system that will be available for all mid and large series models as of April.

At the beginning of the year, Liebherr-France SAS in Colmar, France, started the production of its latest generation of earthmoving crawler excavators. The first phase of the Generation 8 roll out comprises seven new models of between 22 and 45 tonnes.

The R 934 that will be presented at Bauma has an engine that complies with Stage V emission standards. Weighing approximately 35t, the R 934 achieves an engine output of 200kW / 272hp and will be available worldwide with an engine to suit the relevant country's emission standards.

Liebherr's integrated tyre monitoring system helps increase the lifetime of tyres

Terex Trucks

The Terex Trucks team will be at the event to show visitors how the company's two articulated haulers - the TA300 and TA400 - deliver low total cost of ownership and high productivity.

The company's recently updated TA300 articulated hauler will be making its first international tradeshow appearance at Bauma.

"Having recently launched an updated version of the TA300 that boasts improvements in fuel efficiency, performance, productivity and operator comfort, we see Bauma 2019 as the perfect opportunity to display the hauler in front of a global audience," says Paul Douglas, managing director of Terex Trucks. "As well as this, we'll also be using the show as a chance to inform people about our TA400, which is the biggest articulated hauler we make. In terms of maximum payload, it's 10t bigger than the TA300."

The TA300 has incorporated the new EP320 transmission, which comes with two additional forward gears - eight in total - as well as four reverse gears. This helps to ensure smoother gear shifting and thereby superior operator comfort. In addition to this, the TA300 now delivers a 5% improvement in fuel efficiency, as well as enhanced performance, productivity and operator comfort, the company said.

It also now comes with long life transmission fluid, which has helped to increase the length of time between oil maintenance intervals from 1,000 to 4,000 hours. The hauler's maximum speed has also increased to 55km/h, up from 50km/h. Ultimately, the company says, this means that customers can achieve faster cycle times, reduce the cost of operation per tonne and minimise their fuel consumption.

Terex Trucks' recently updated TA300 articulated hauler