Background

The requirements for explosives have been changing. Higher performance and increased safety are the overriding objectives which are demonstrated above all in the greater use of emulsion explosives. In Switzerland alone - traditionally a country with a great deal of tunnel construction - the ratio changed between 1998 and 2005 from 100 percent explosives in cartridge form to 95 percent pumped emulsions. The benefits are huge: the components, which are not dangerous individually, are not mixed until they are on site. The finished mix fully uses the whole borehole, but also goes into small openings. Certainly, high-performance, customised pumps which meet the special challenges of the emulsion matrix or of the explosive are the basis for this.

Challenge

This type of explosive material certainly requires special conveyance conditions. In the German Accident Prevention and Insurance Association's Regulations (BGV) for solid uniform explosives and for blasting oils, it is for instance stated that pumps should prevent a dangerous strain on the materials or a separation of the emulsion.

Solution

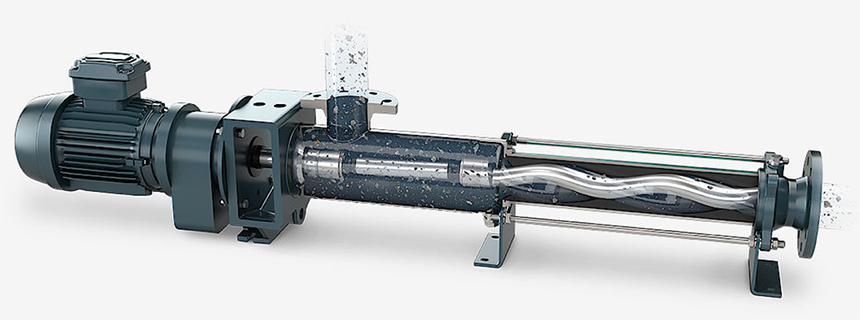

The pump specialist NETZSCH has therefore developed special equipment for mobile mix loading vehicles to convey emulsified explosives. The proven NEMO®SY progressing cavity pump has therefore been extensively reworked to implement the necessary testing possibilities and safety measures. The two inspection openings which have been incorporated above the joints of the coupling rod are the greatest difference with respect to conventional designs. These mean that it is possible to check whether the joints are still sufficiently lubricated and the seals are still intact while the pump is in operation. Otherwise the metal on metal friction could lead to dangerous heat generation. The explosives pumps are ATEX-concurring and built for the individual requirements of the costumer.

Products

Nemo By

NEMO® BY Progressing Cavity Pumps can be used in any area of industry where a great variety of different substances must be pumped or very precisely dosed. From low viscosity media to products barely capable of flowing, with or without solid content, shear-sensitive, sticky or abrasive - with the NEMO® BY, even difficult substances are conveyed gently and under low pulsation.

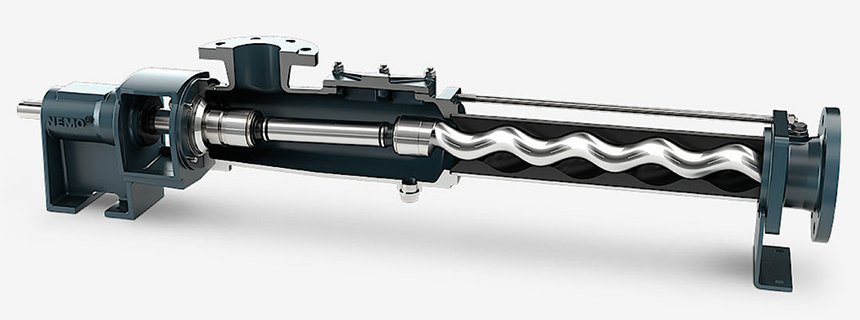

Nemo Sy

The NEMO® SY Progressing Cavity Pump is used for demanding applications in every branch of industry around the globe. In bearing block design with free shaft extension, this pump can be run with any type of drive, such as servo motors, diesel motors or hydraulic drives. The pump can also handle high-pressure applications. Four rotor/stator geometries are available, enabling the pump to be customized perfectly to your application case. The NEMO® SY is suitable for all branches of industry where low- to mid- viscosity and/or shear-sensitive, abrasive or adhesive media must be safely and gently conveyed

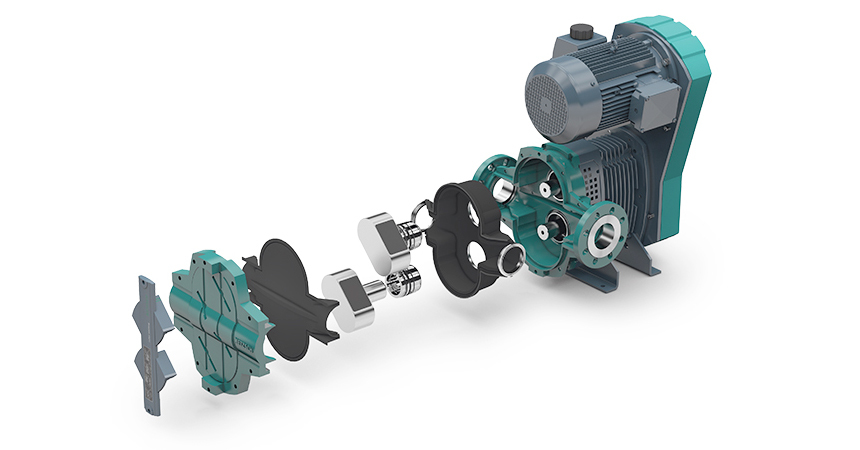

Tornado T2

NETZSCH TORNADO® industrial rotary lobe pumps are versatile stand-alone equipment. Used primarily in environmental technology and the chemical industry, these pumps handle almost any substance continuously and gently while metering in proportion to rotation speed. Their small space requirements and high power density are some of their most important advantages.

ABOUT THIS COMPANY

Netzsch

For more than six decades, NETZSCH has manufactured positive displacement pumps worldwide. The NETZSCH ranges of NEMO® progressing cavity pumps and TORNADO® rotary lobe pumps are designed specifically for the most demanding pumping applications. NETZSCH pumps range in size from the industry’s smallest metering pumps to high-volume pumps for de-watering duties in the mining industry.

Contact details

Roger Willis

Business Field Manager Chemical, Pulp & Paper

Phone: +498638/63-0

E-Mail: info.nps@netzsch.com