The use of real-time data in underground mining has moved beyond a "nice to have" and is now essential for any operation looking to drive productivity and promote maximum health and safety of its workers.

As the reliance on data and real-time information has soared, the ability to transfer this data across the entire mining environment, in real-time, has become a large focal point in modern-day mining. Infrastructure creation, expansion and on-going maintenance play a significant role in day-to-day operations.

Remote Monitoring, Control & Command

Being able to monitor underground environments in real time, and receive early warning alerts of potential danger, has now become fundamental to any operation.

Whether it is monitoring the atmosphere for the presence of dangerous gasses, measuring air flow for adequate ventilation, or evaluating the concentration of harmful dust particulates, real-time monitoring is vital for ensuring that operators stay ahead of potential problems. Today, we can also go a step further and deliver this data to the surface in real-time. This not only helps to eliminate time consuming and laborious in-person inspections, but also ensures proactive, continuous monitoring coverage in all locations.

Add then the capability to remotely control underground devices and Programmable Logic Controllers (PLCs) on systems, and the mine can operate highly efficiently and with increased safety.

Communication

There are different options in voice communication today. Leaky feeder radio remains one of the most popular choices, and wireless access for Voice-over-IP and cellular calling have become very real options with fiber optics. The use of Wi-Fi and cellular access points along fiber, however, can be restrictive in placement locations. The pre-set cable lengths and technical involvement of tapping into fiber, dictates the placement location of access points. Areas of the mine, such as the "last-mile" working section, or isolated/remote areas will often be lacking in access to digital voice.

Expanding the infrastructure

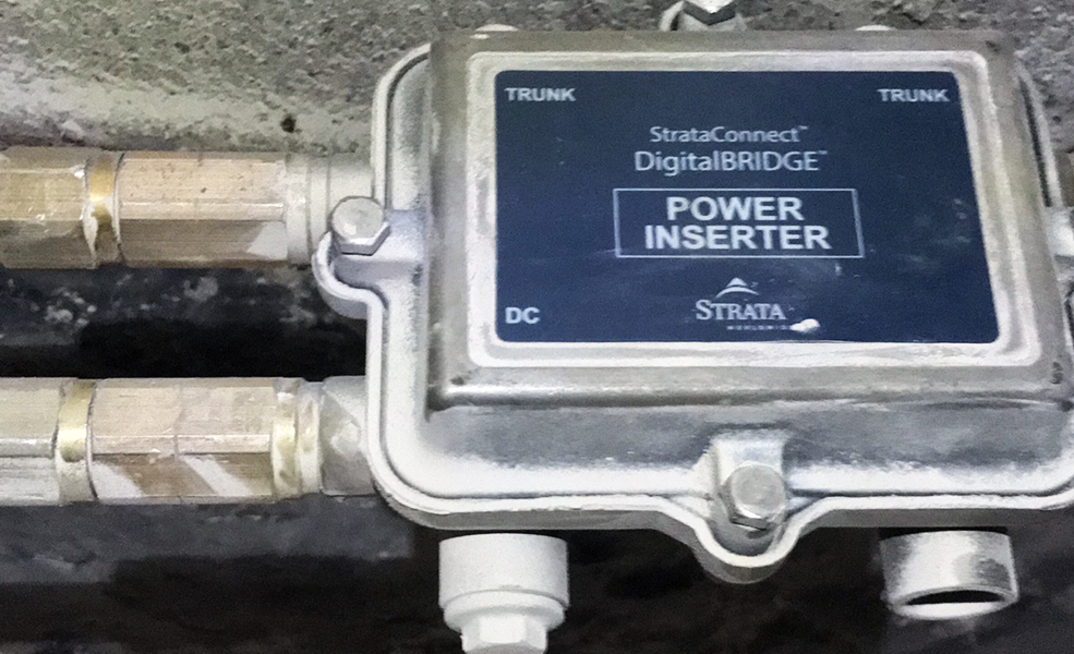

StrataConnect DigitalBRIDGE and DigitalBRIDGE Plus+ and new, innovative solutions that can help overcome many of the typical constraints experienced with traditional underground networks. They leverage existing infrastructures and offer low cost, user friendly means to expand, enhance, repair, or even replace them.

DigitalBRIDGE and DigitalBRIDGE Plus+ combine the strengths and user benefits of existing networks and bring them together into a single, multi-functional system. They also provide the additional benefit of carrying DC power for powering components and end-point devices.

The primary function of these systems is to create a highly versatile, high-speed digital network for the inclusion, and powering, of mine-preferred Ethernet end-point devices. These include wireless access points for voice communications and high-speed data, video surveillance, RFID tracking, instrumental telemetry, gas detection and more.

StrataConnect DigitalBRIDGE is a point-to-multipoint Power-over-Ethernet (PoE) network which carries both high-speed Ethernet and 48 to 60VDC over a single cable. It uses an industrial-grade coaxial cable that is ideal for extending high-speed digital coverage beyond the reach of fiber, and into areas where it is challenging to install fiber. Interfacing into the fiber optic network at any underground network switch, mines can run the coaxial cable to any location and in multiple directions. Power can be inserted into the line at any point and will travel through the network in both directions.

Using standard tools and simple procedures, mine personnel can tap into the coaxial cable at any point to integrate and power off-the-shelf Ethernet devices.

StrataConnect DigitalBRIDGE Plus+ leaky feeder network carries Ethernet data, DC power and a full spectrum of VHF radio frequencies over a single cable, without affecting the quality of radio communications. It leverages the convenience and dependability of leaky feeder networks and incorporates the power and functionality of DigitalBRIDGE's PoE technology. DigitalBRIDGE Plus+ line amplifiers with Ethernet provide a link to the mine's network and introduce high-speed Ethernet into the leaky feeder.

Using standard tools and simple procedures, mine personnel can tap into the leaky feeder cable at any point and integrate the DigitalBRIDGE QuadPort for the inclusion and powering of many mine preferred off-the-shelf PoE Devices.

Bridging the Gap to Emergency Refuge

Both DigitalBRIDGE and DigitalBRIDGE Plus+ can be used to extend the mine's existing network to connect to the underground emergency refuge shelters in place. This facilitates ongoing preventative maintenance to ensure the refuge shelter remains operationally ready.

In the event of an emergency where workers retreat into the shelter to await rescue, this connectivity opens a life-line of communications to the surface and rescue teams, as well as provides the ability to actively monitor the integrity of the enclosed environment and select operating status of chamber systems.

ABOUT THIS COMPANY

Strata Worldwide

Strata Worldwide is a leading global supplier of safety products, services and technologies for the mining and tunnelling communities. With a comprehensive line that promotes greater safety across all types of mines and facilities, Strata brings state-of-the-art solutions to its customers while providing high-quality customer support throughout the business process.

CORPORATE HEADQUARTERS

- 8800 Roswell Road, Suite 145, Sandy Springs, Georgia 30350

- Phone: +1-770-321-2500

- Fax: +1-800-691-6601

- Email: info@strataworldwide.com

- Web: www.strataworldwide.com