By offering processing and recycling solutions, the leading machinery supplier has created a ‘closed loop' end-to-end service for battery minerals customers. With the electric vehicle (EV) revolution firmly under way and the energy transition at the forefront of everyone's mind, battery minerals have fast become one of the most in-demand resources on the planet.

For mining players - as well as the users of their products - the production and recycling of battery minerals (primarily lithium, nickel and cobalt) are aspects of their business that are taking up ever greater amounts of airtime and resources.

It is therefore essential that the key players partner with businesses that can produce and recycle these minerals not only in the safest and most efficient way, but also in a way that maintains the highest possible standards when it comes to sustainability. After all, there is little point in producing the metals that enable the energy transition in a way that is itself unsustainable.

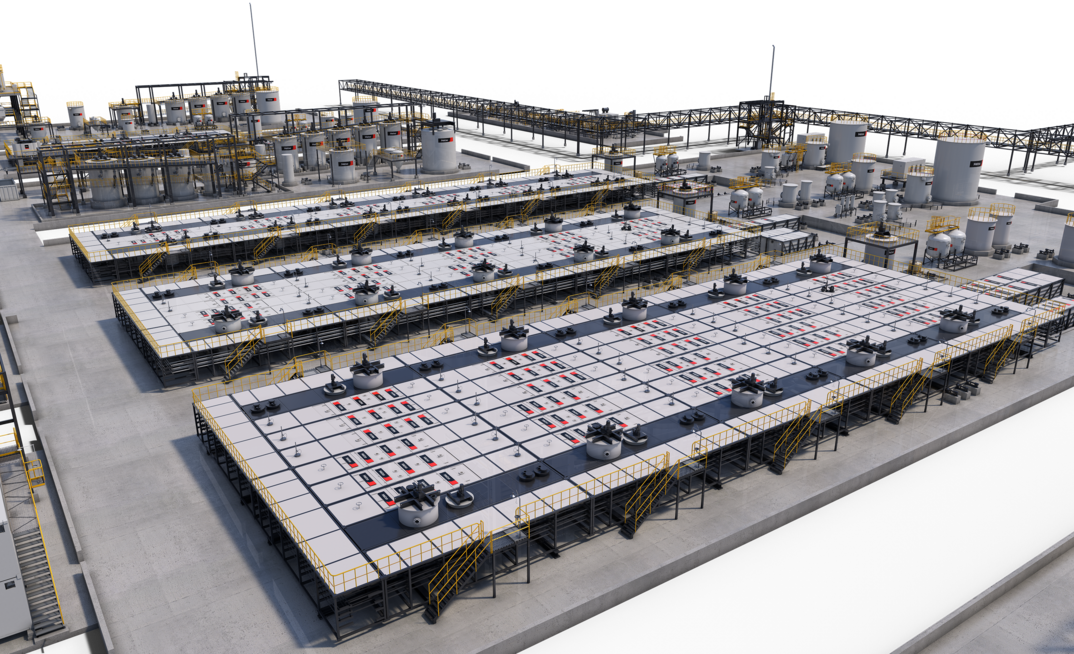

Metso Corporation's launch of its battery black mass recycling process means that the leading end-to-end solutions and services supplier for the aggregates, minerals processing and metals refining industries can now offer a complete end-to-end service for the production and recycling of battery minerals.

Mikko Rantaharju, Vice President, Hydrometallurgy at Metso, has no doubt about the scale of the rapidly expanding market for both the production and recycling of battery minerals: "When we are looking at the composition of batteries in EVs, the amount of lithium, nickel and cobalt needed is something totally different than it used to be in small electronics," he explains. "We definitely see that there's a demand, and that demand puts the prices up.

"There's a lot of investors and a lot of new players coming into the market: the known mining players are expanding their value chain downstream; and then there are EV OEMs (Original Equipment Manufacturers) or even chemical producers that are expanding their value chain upstream."

And Rantaharju believes that Metso has a distinct advantage in being able to provide a holistic approach to the production and recycling of battery minerals.

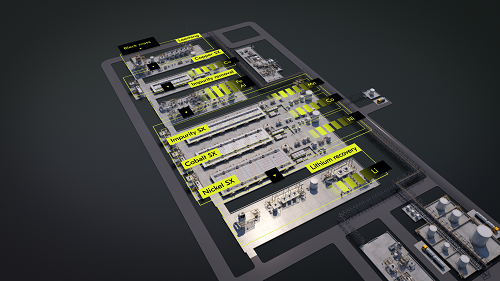

"Our offering covers complete processes and services from minerals extraction to refined battery chemicals and end-of-life battery black mass recycling. Today, we can provide sustainable technology and equipment for the entire lithium, nickel and cobalt production chains. Equally important is the fact that we can support our customers in process design with our comprehensive testing and research capabilities."

"Now, many of the processes used in concentrator plants and base metals refining can be utilized in battery recycling as well, enabling the plant operator to recover the most valuable minerals and metals from the black mass and at such a purity that they can be then used again, for example, as battery precursor materials."

It is an example of how Metso's solutions help create a ‘closed loop' and contribute towards the circular economy.

Metso Battery minerals processing

Metso's hydrometallurgical battery black mass recycling process - like many of the technologies used in concentrator plants - is part of the company's Planet Positive offering,

"Definitely we want to have Planet Positive, sustainable processes and equipment and we put a lot of effort to develop the best in class," says Rantaharju, who acknowledges that producing these battery components is essential to the green energy revolution.

He gives the example of lithium hydroxide production from lithium concentrate as an illustration of how Metso uses its unique processes in a more sustainable way, contributing to the circular green economy. The company uses alkaline - rather than acidic - leaching media, which means that it does not produce soluble sulphates and sodium sulphate as leaching residue by-products which are difficult to process and harmful to the environment. Instead, the Metso technology produces inert material, analcime sand, which can safely be used in landfill or even on construction and infrastructure purposes.

And the sustainability agenda is carried through to the way that Metso approaches its client services too. Metso offers lifecycle, professional and maintenance services to make sure that the life of whatever plant is required by customers runs as smoothly as possible and has the maximum amount of availability. This is not just the right approach for customers but is also part of the wider Planet Positive ethos.

Rantaharju says that the services offering must also adapt to a potential new range of clients in the battery minerals recycling space: "We see that this market is developing so fast, and new players are entering the market and establishing their presence. These are not always the old mining customers and they might have sightly different demands as well."

He cites digitalisation as one way that Metso is helping its customers make the most of the technology it is supplying them. For example, the company can accurately simulate the effect on a flowsheet for a customer that is refining lithium coming from a range of suppliers at a variety of different grades, so production can be optimised and run as smoothly as possible.

Metso's offering across this space is constantly evolving to match customer demand. As Rantaharju explains, this evolution has been a feature for some time: "We've been supplying equipment to concentrators producing lithium for years and years. Now, we are also focusing on the hydrometallurgy side and on the metals refining side and are constantly developing our own proprietary offering. And then now this summer, we launched the battery recycling offering."

"So we are always actively developing our offering in this field, and there's new development coming. We can do this because of our unique testing and development capability and our highly skilled people. There's definitely more to come."

ABOUT THIS COMPANY

Metso

Metso is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. We improve our customers’ energy and water efficiency, increase their productivity, and reduce environmental risks with our product and service expertise.

HEAD OFFICE:

- Rauhalanpuisto 9, 02230, Espoo, Finland

- Phone: +358 20 484 100

- Web: www.metso.com/