Even experienced mine planners tend to oversimplify cover systems, referring to them as ‘caps' or ‘capping', and assuming cover systems to be only a couple of metres of overburden and topsoil.

The reality is that an engineered cover system can serve various functions: limiting net percolation, controlling oxygen ingress, limiting the egress of radiation, managing erosion, isolating chemically reactive waste material, reducing the volume of impacted surface water, and providing growth media for re-establishing ecosystems.

Understanding site-specific requirements and designing cover systems accordingly laid the foundation that established Okane Consultants over 25 years ago. Mike O'Kane, the founder of the company, is still active as a senior technical advisor, and often presents the analogy, learned from his mentor Dr Lee Barbour, that designing a cover system is like building the right-sized flowerpot.

Well-designed cover systems require a careful balance of water, gas, and energy. When executed effectively they are part of an integrated landform design and should support returning or future land use objectives.

Technical closure practitioners who jump to a ‘capping' design without considering the long-term objectives for the site are missing a key piece of the closure puzzle. The team at Okane has always been curious about breaking down a cover system and landform design to its core closure objectives (understanding the drivers dictated by the potential future land use and acceptable residual risk). In other words, they seek to define the ‘why' of a cover system.

The first step in a cover system and landform design should be the same as the first step in integrated closure planning: developing a clear closure vision. Defined by ICMM in 2019 as an "aspirational description of what will be achieved with mine closure, compatible with regulatory requirements", closure visions cannot be developed in isolation. Mine sites planning for closure need to navigate a range of local and international regulatory requirements, industry standards and best practices, as well as evolving stakeholder expectations.

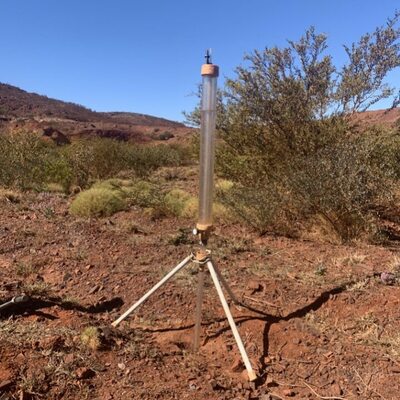

Soil monitoring station data acquisition system.

Developing a mine closure vision needs to go beyond the resolution of environmental risks and meeting minimum regulatory requirements, especially for long-operating mine sites that have become foundational aspects of surrounding communities. It also needs to consider socioeconomic and community transition, alongside long-term regional economic stability. So, to develop a closure plan that meets all these requirements while managing sometimes conflicting expectations, it is critical for mine operators to establish and gain alignment on a closure vision with stakeholders, Indigenous rightholders, and regulatory bodies.

This process requires divergent and aspirational thinking, something many engineers and geoscientists have little experience with. This is why successful integrated mine closure planning must be interdisciplinary in nature, as opposed to simply multidisciplinary, as the latter approach can cement silo mentalities. Technical experts in all fields must be brought together to leverage domain expertise to achieve shared outcomes.

To nurture and facilitate the requisite approach, Okane advocates for and facilitates closure vision workshops. These workshops aim to uncover the highest value future land use potential and are then used as the basis from which to define clear closure objectives.

Okane also recognises the need to challenge the language mine closure practitioners use. For example, operators and regulators use the term ‘end land use' to describe the future of post-mining, mine-affected lands, where Okane believes ‘returning land use', or ‘future land potential' would be more appropriate.

This shift in description causes closure visioning to consider the long-term legacy of mine-affected landscapes. In Okane's view, ‘end land use' acts to reduce land to a status solely within the context of immediate post-mining risk management, rather than considering the potential opportunities for mine-affected land. Moreover, it discounts the historical and future significance of the land to affected communities and Indigenous rightsholders.

It is the same reason Okane uses the term ‘mine rock' instead of ‘waste rock'.

To illustrate the point, Okane had cause to change its perspective through its engagement with the Ktunaxa Nation, whose Traditional Territory is in the Kootenay region of southeastern British Colombia, as well as parts of Alberta, Montana, Washington, and Idaho (Ktunaxa Nation, 2022).

In discussions regarding the management of metal leaching from waste rock dumps on the site, an Elder explained to Okane that referring to the rock as ‘waste rock' was disrespectful to his People. Since the mountains being mined held significance to the Ktunaxa Nation's creation story, by extension, the description aligned his ancestors with waste (Okane, 2022).

Guelph permeameter measuring soil saturated hydraulic conductivity.

At the North Coal Michel Coal project, mine rock storage facilities are being designed to manage source term, and not be entirely reliant on a cover system alone. This approach involves placing the mine rock in such a way as to manage the re-supply of oxygen and limiting oxygen movement in the stockpile to minimise potential future adverse impacts. It is part of Okane's collaborative approach that seeks to return the land to a state that is useful and desirable for communities.

Also in Canada, Okane has been working for several years on the environmental award-winning Project CLEANS in partnership with Saskatchewan Research Council, where it has been leading the design of tailings cover systems at an abandoned uranium mine and mill. And in Western Australia, Okane's work on Westgold's Lady Rosie operation has led to the adoption of a geomorphic landform design for a mine rock stockpile for improved environmental outcomes.

The repositioning of mine-affected lands as hubs of opportunity, along with the valorization of mining waste/byproducts continues to gain traction as Environmental, Social, Governance (ESG) investment criteria increase the pressure on mine operators to act more responsibly.

Unfortunately, the 'E' in ESG too frequently gets reduced to emissions, rather than being concerned with a company's wider stewardship of the physical environment. Consequently, many mine operators limit their focus to carbon accounting and meeting net zero commitments.

However, land and water management are just as important as carbon management, and this is an area where experienced mine closure practitioners can add true value to mining operations.

The team at Okane advocates strongly for a full lifecycle approach to land stewardship, so that mine-affected lands can create opportunities for emissions reduction post-closure. They point to the potential for a mine rock stockpile to create an elevated landscape and therefore higher windspeed for wind turbines, designing the landform and its orientation to maximise opportunity for solar farms, or the prospects for pumped hydro at mine sites with pit lakes at differing elevations (Okane, 2023 ).

The days of designing cover systems and landforms in isolation have been consigned to history, and rightly so. Today, mine closure practitioners need to be curious about the legacy of mine-affected landforms to manage long-term risks and find post-closure opportunities throughout the life of mine (LOM) as part of an integrated mine closure planning approach.

While this modus operandi is increasingly being adopted by mining companies, Okane notes that in most cases, it falls short of true integration, as most operators still manage their LOM and closure plans as separate documents. This means the closure plan is often ‘left behind' as material changes to the LOM plan take time to filter through.

It is why Okane advocates for one, fully integrated life of mine operating and closure plan; a call to action being driven by the same curiosity that saw its mine closure practitioners come to understand the ‘why' of cover systems.

Okane's efforts are starting to bear fruit, with a marked increase in the number of interdisciplinary teams made up of all the traditional mine closure technical disciplines and mine planners. These teams consider the full lifecycle impacts of material characterisation and management in the LOM plan to establish long-term geotechnical and geochemical stability during operations.

Mine rock stockpiles are, for example, all too often designed and constructed with a focus on the ‘lowest cost' and most geotechnically stable way to place rock. Only after are environmental risks considered, increasing the risk of mine rock stockpiles becoming long-term liabilities as major sources of acid mine drainage post-closure.

Imagine if how the materials were placed during operations could significantly reduce post-closure liability? If we could build a geotechnically stable mine rock stockpile for the lowest cost, and achieve geochemical equilibrium?

That is the philosophy behind the International Network for Acid Prevention's ‘Rock Placement Strategies to Enhance Operations and Closure Performance on Mine Rock Stockpiles' (INAP, 2020). Having led the development of this guidance document, Okane's integrated, interdisciplinary teams seek opportunities to achieve source term control in mine design to minimise post-closure liability. Okane employs sophisticated deterministic and probabilistic numerical models to design landforms for long-term risk reduction while preserving future land use potential.

Okane sees the future of integrated mine closure planning as the breaking down of silos between technical disciplines, mine planning, and socioeconomic considerations. It also deems full interdisciplinary teams to be critical in managing post-closure risks while uncovering future land use potential. Above all, Okane believes integrated mine closure planning must be underpinned by a culture of curiosity, alongside a practised approach to looking beyond the cover system.

ABOUT THIS COMPANY

Okane Consultants

Okane helps mining companies to return the land responsibly and safely at the end of a mine’s lifecycle. We believe in challenging the status quo and advocate for meaningful partnerships and positive outcomes for community stakeholders and Indigenous rightsholders. Our solutions help our clients achieve positive financial, environmental, and social outcomes from feasibility through to relinquishment.

HEAD OFFICE:

112 – 112 Research Drive

Saskatoon, SK, S7N 3R3

Canada

Tel: +1 (306) 955 0702

SOCIAL: