Our integral grinding and crushing solutions are designed to add substantial value to the efficiency, effectiveness, and profitability of your grinding and crushing processes. These solutions aim to optimize operations by streamlining processes, improving productivity, and maximizing profitability in both grinding and crushing activities.

Fully Integrated Technology

ME FIT System®: Fully Integrated Technology

The ME FIT Crushing and ME FIT Grinding optimization programs leverage over a century of expertise in the mining, aggregate, and recycling industries. Tailored specifically to address the unique challenges of each mining operation, our customized solutions are crafted to support our customers' production strategies and productivity goals.

Through the ME FIT System programs, we offer integrated solutions that deliver tangible value to our customers' processes. These solutions are meticulously engineered to significantly enhance productivity, resulting in more efficient and effective operations. At ME Elecmetal, our dedication lies in elevating the performance and success of our clients within the mining sector.

VAP Philosophy

ME Elecmetal's Value Added Philosophy extends far beyond a mere work methodology; it is a strategic framework for surmounting intricate technical challenges. Our philosophy is firmly rooted in the concept of delivering comprehensive solutions that enhance the value of mining processes. This approach has been an integral aspect of our operational strategy for many years, facilitating the establishment of enduring relationships with our clients founded on trust.

At ME Elecmetal, our unwavering commitment is to provide innovative products, services, and solutions that contribute tangible value to our clients' operations. We are dedicated to adding efficiency, sustainability, and excellence to every facet of our client partnerships.

Products, Services, and Solutions Designed to Create Significant Value

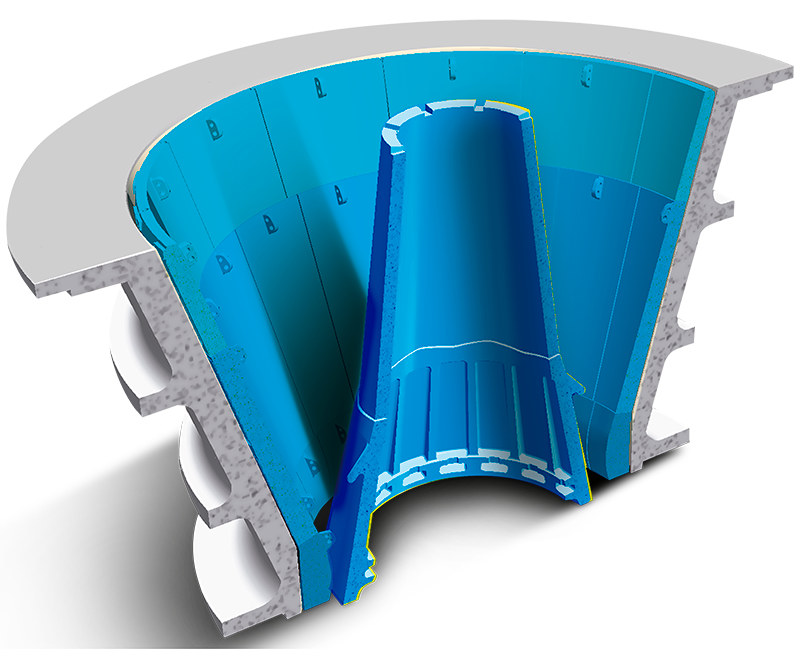

Mill Liners

Grinding mill liners are essential for achieving optimal mill performance. At ME Elecmetal, we are committed to providing innovative liner and alloy designs that not only deliver proven performance but also minimize costly relines and downtime. Our team works in close collaboration with customers to comprehensively analyze their operations and identify the optimal combination of design and materials for their equipment. Each liner is meticulously customized to ensure the best possible performance, and we closely monitor wear performance and production rates at every stage of the process.

Our solutions consistently surpass customer expectations, offering the lowest total cost of ownership. You can trust us to uphold the highest quality standards and employ state-of-the-art technology to ensure superior strength and durability, enabling you to operate your mills with confidence and efficiency.

Grinding Media

ME Elecmetal stands as a premier supplier of top-tier forged steel grinding media for SAG, ball, tower, and rod mills worldwide. Our extensive field experience and engineering proficiency make us invaluable partners in facilitating continuous improvement within your grinding processes. Our dedicated team of sales and application engineers is readily available to analyze operational data, refine media charging practices, and optimize grinding media consumption, ultimately enhancing throughput.

You can place your trust in us to deliver the grinding media to your site and to provide steadfast support until your final product emerges from the mill. Our substantial experience and large-scale grinding media production capacity have solidified ME Elecmetal's status as a strategic partner in the global mining market, working alongside you to attain operational excellence and efficiency.

Crusher Wear Parts and Safety Tooling

Looking for optimal Crusher Wear Parts for your mining, aggregate, or recycling industry needs? Look no further than ME Elecmetal, the leader in wear solutions for crusher operators. Our alloys and designs are specifically developed for each application, providing solutions for primary, secondary, and tertiary crushing. We pride ourselves on tackling any customer challenge while maximizing benefits. Safety, durability, and ease of use are our top priorities, and we also offer a full line of Crusher Safety Tooling products designed to help you get the job done safer, faster, and smarter. Trust us to adapt our solutions to any type of equipment on your site, ensuring optimized performance and longevity.

Digital Solutions

Innovation Driven by Experience and Technical Knowledge

Optimization Tools and Services

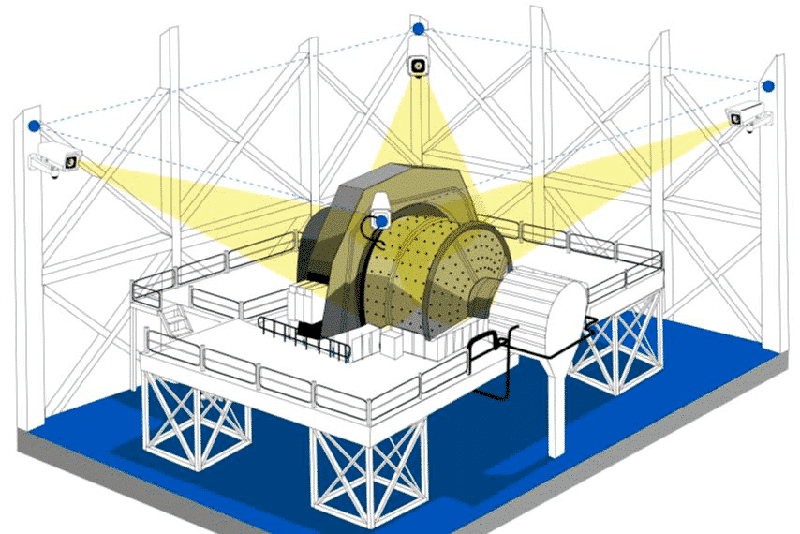

ME Elecmetal's advanced grinding and crushing solutions are spearheading a revolution in the mining industry. Harnessing the power of digital tools to analyze vast volumes of data, we're able to craft customized solutions designed to tackle your unique challenges. Our optimization tools, including wear monitoring, enhance operational efficiency and provide real-time insights.

But our commitment doesn't stop there. We go above and beyond with our technical support and training services, offering a comprehensive range of options. This includes cutting-edge offerings like 3D laser scanning for wear analysis, reline optimization, and continuous improvement programs.

ME Elecmetal is dedicated to taking your mining operations to the next level, providing you with the tools and expertise to optimize your processes and boost your productivity. Discover how we can help you unlock the full potential of your mining endeavors.

Contact Us Today!

ME Elecmetal has been a leading global supplier for over a century, providing total wear product solutions for mineral processing, aggregate, construction, and recycling industries. With a wide range of products and services, including grinding media, mill liners, crusher liners, and specialty castings, ME Elecmetal is the go-to supplier for mineral processors seeking to optimize their grinding mill processes. And with 1,200+ employees and customers in 35+ countries worldwide, you can trust ME Elecmetal to provide the expertise and support you need to succeed. Learn more about our ME FIT System and other programs at www.me-elecmetal.com or call 480-730-7500.

ABOUT THIS COMPANY

ME Elecmetal

ME Elecmetal is a global supplier with more than 100 years of experience as a supplier and strategic partner for total wear product solutions in the mineral processing, aggregate, construction and recycle industries. We are the preferred supplier for mineral processors seeking improvements in their grinding mill processes. Our range of products include: grinding media, mill liners, crusher liners, large specialty castings, slag pots and ground engaging tools. Our range of services include: service centers, engineering and design, Early Alert and ME FIT System®. ME Elecmetal has 1,200+ employees and serves customers in 35+ countries around the world.

United States Offices

- 4500 S Lakeshore Drive, Tempe, AZ 85282, 480-730-7500, United States

- 3901 University Ave NE, Minneapolis, MN 55421, 763-788-1651, United States

- Tel: 4807307500

- Email: marketing@meglobal.com

- Website: www.me-elecmetal.com