Mill Liners for Optimal Results: Enhancing Efficiency with Customized Liner Solutions

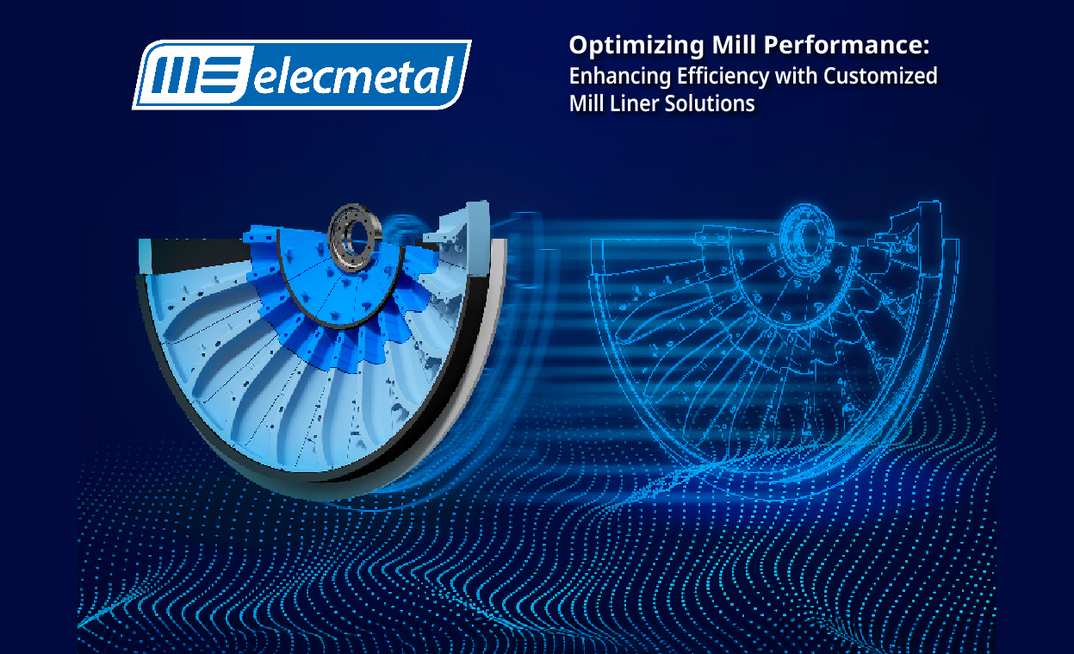

Through close collaboration with our customers, ME Elecmetal meticulously analyzes each application to determine the best combination of design and materials, ensuring optimal wear performance and throughput for AG, SAG, ball, rod, and tower mill liners.

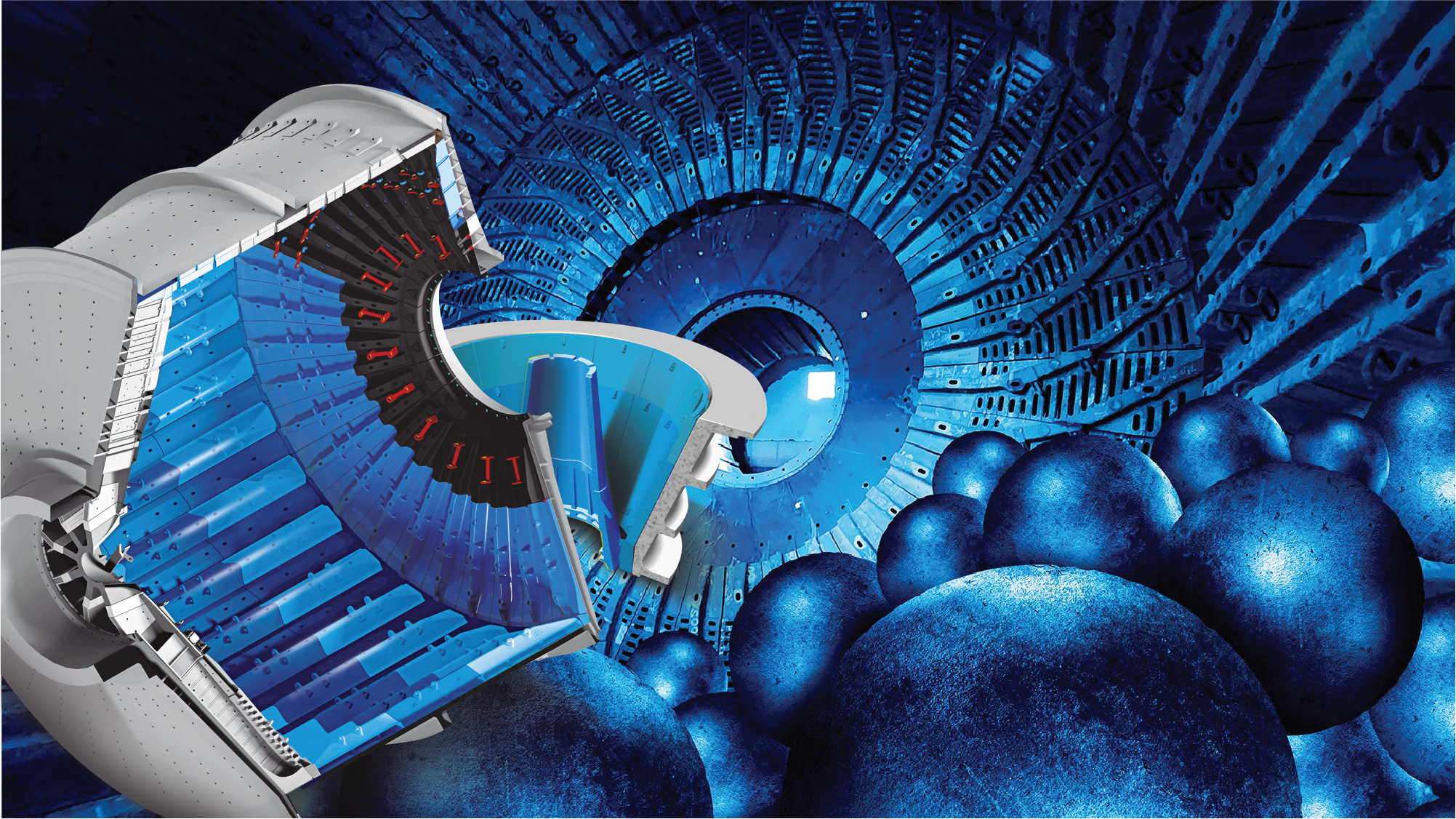

Grinding mill liners are critical to achieving peak mill performance. At ME Elecmetal, we prioritize innovation in liner and alloy designs, focusing not only on delivering proven performance but also on minimizing costly relines and downtime. Through close collaboration with our customers, ME Elecmetal meticulously analyzes each application to determine the best combination of design and materials, ensuring optimal wear performance and throughput for AG, SAG, ball, rod, and tower mills. Each liner undergoes detailed customization to ensure unmatched strength and durability, with continuous monitoring of wear performance and production rates throughout the process.

Earning our customers' trust is paramount. We achieve this by offering technical solutions with substantial benefits and minimal risks. Our solutions consistently surpass customer expectations, offering the lowest total cost of ownership. Customers can rely on us to uphold the highest quality standards and utilize cutting-edge technology, enabling them to operate mills with confidence and efficiency. Our liners are engineered to excel in both high-impact and high-abrasion applications, regardless of mill type. ME Elecmetal provides a comprehensive suite of services, including condition monitoring, to further enhance efficiency and deliver real-time insights to our customers.

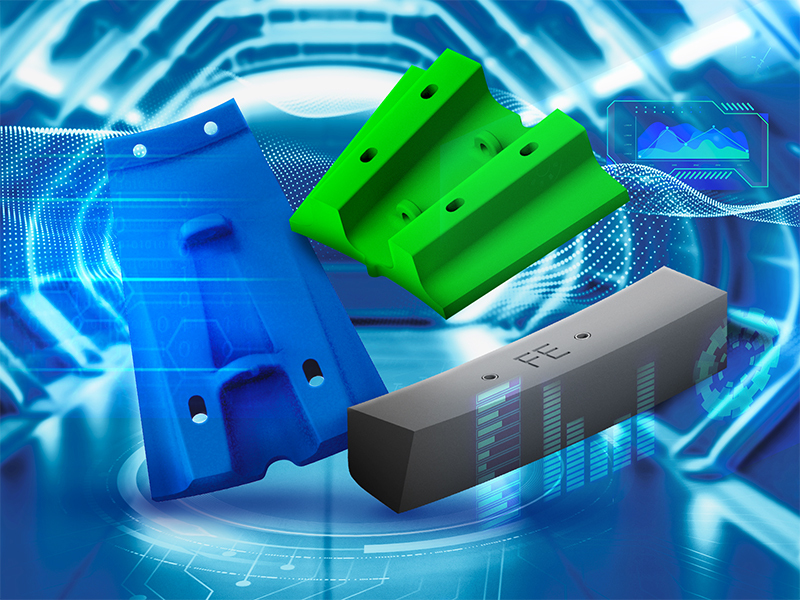

We are dedicated to developing the next generation of alloys to boost wear performance and grinding efficiency. By analyzing our customers' operating conditions and leveraging our extensive global knowledge base, we craft optimized solutions. We then collaborate closely with our customers to implement and validate these solutions.

We partner with our customers by thoroughly understanding their needs. We gather comprehensive operational data, including processed tonnage, available power, downtime, load levels, and more. We evaluate media and liner longevity, and production levels, and identify opportunities for process improvements.

Recognizing that changes in mining processes can impact both current and downstream operations, we conduct extensive simulations and tests before proposing any modifications. This ensures that our solutions minimize risks and avoid adverse effects.

ME FIT®: Fully Integrated Technology

Drawing on more than a century of experience in the mining, aggregate, and recycling sectors, ME Elecmetal's ME FIT Crushing and ME FIT Grinding optimization programs provide customized solutions to tackle the specific challenges of each mining operation. Our goal is to assist customers in realizing their production strategies and productivity targets.

With our ME FIT Programs, we offer comprehensive solutions that bring tangible benefits to our customers' operations. Engineered to boost productivity significantly, these solutions enable more streamlined and efficient processes. ME Elecmetal is dedicated to continuously improving the performance, efficiency, sustainability, and success across all facets of our client partnerships. This commitment fosters enduring relationships with our clients, rooted in trust.

Optimization Tools and Services for Continuous Improvement

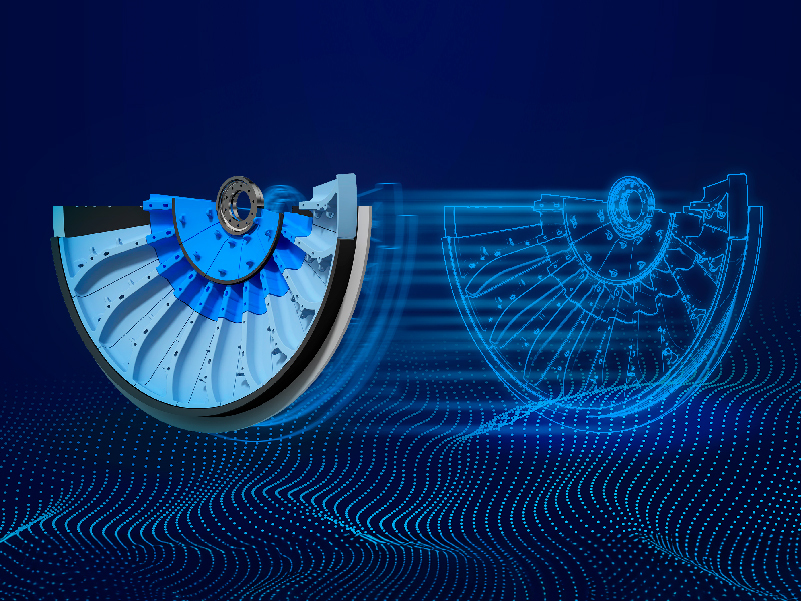

ME Elecmetal leads the mining industry with innovative digital tools that transform grinding and crushing operations. Our approach goes beyond conventional methods by utilizing large-scale data analysis to create customized solutions that tackle specific challenges, enhancing operational efficiency and productivity. Our optimization suite offers valuable insights and wear monitoring, ensuring data-driven decisions for peak performance.

Our commitment extends beyond providing innovative tools. We offer exceptional technical support and training to empower clients and their teams with the skills needed for optimal performance. Our services include 3D laser scanning for precise wear analysis, reline optimization to reduce downtime, and continuous improvement programs to promote operational excellence.

At ME Elecmetal, we understand that success in the mining industry requires advanced technology and unwavering client support. We provide the tools, knowledge, and ongoing assistance necessary to elevate your mining operations. Discover how ME Elecmetal can help unlock the full potential of your mining ventures.

Contact Us Today!

You can rely on ME Elecmetal to provide the expertise and support necessary for your success. Discover more about our ME FIT Programs and other solutions by visiting www.me-elecmetal.com or contacting us at 480-730-7500.

About ME Elecmetal

ME Elecmetal is a leading global supplier and strategic partner in the mining industry. Renowned for its commitment to innovation and technology, ME Elecmetal is dedicated to delivering cutting-edge, sustainable solutions that exceed customer expectations worldwide.

With a broad range of products and services, including grinding media, mill liners, crusher liners, and large specialty castings, ME Elecmetal is the preferred partner for mineral processors seeking to optimize their grinding mill processes.

The company operates seven metallurgical plants across Chile, the USA, Peru, China, and Zambia, boasting a manufacturing capacity of 134,000 tons for foundry products and 600,000 tons for grinding media. ME Elecmetal's commercial presence extends to over 40 countries, reinforcing its position as a global leader in the mining sector.

ABOUT THIS COMPANY

ME Elecmetal

ME Elecmetal is a global supplier with more than 100 years of experience as a supplier and strategic partner for total wear product solutions in the mineral processing, aggregate, construction and recycle industries. We are the preferred supplier for mineral processors seeking improvements in their grinding mill processes. Our range of products include: grinding media, mill liners, crusher liners, large specialty castings, slag pots and ground engaging tools. Our range of services include: service centers, engineering and design, Early Alert and ME FIT System®. ME Elecmetal has 1,200+ employees and serves customers in 35+ countries around the world.

United States Offices

- 4500 S Lakeshore Drive, Tempe, AZ 85282, 480-730-7500, United States

- 3901 University Ave NE, Minneapolis, MN 55421, 763-788-1651, United States

- Tel: 4807307500

- Email: marketing@meglobal.com

- Website: www.me-elecmetal.com